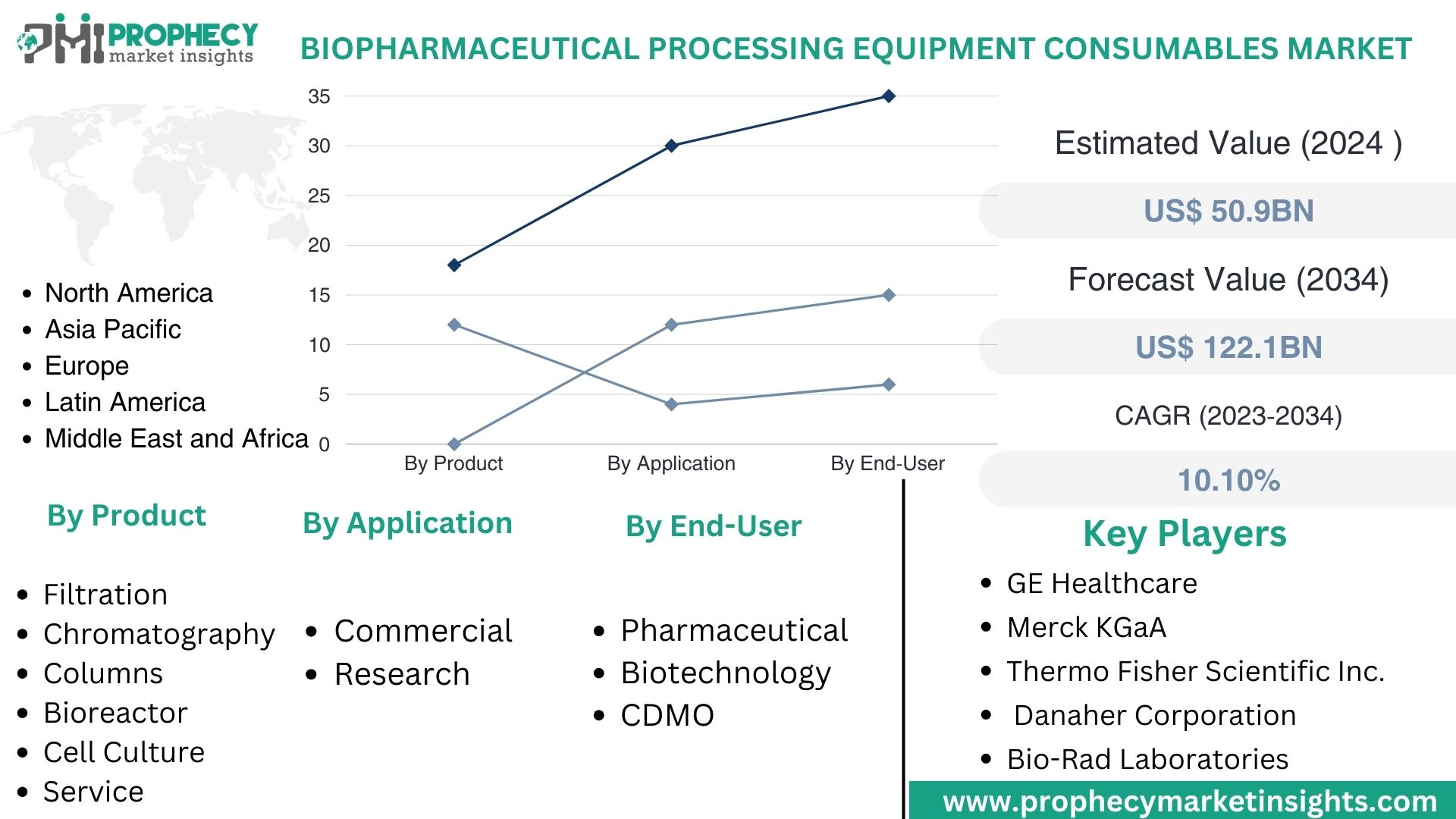

Covina, Feb. 23, 2024 (GLOBE NEWSWIRE) -- “According to the recent research study, the Biopharmaceutical Processing Equipment Consumables Market size was valued at about USD 50.9 Billion in 2024 and expected to grow at CAGR of 10.10% to extend a value of USD 122.1 Billion by 2034.”

What is Biopharmaceutical Processing Equipment Consumables?

Market Overview:

Biopharmaceutical processing equipment consumables refer to the various supplies, materials, and components used in the manufacturing and processing of biopharmaceutical products. These consumables play a crucial role in biopharmaceutical production processes, facilitating the handling, processing, and purification of biologics such as vaccines, monoclonal antibodies, recombinant proteins, and cell therapies.

Biopharmaceutical processing equipment consumables encompass a wide range of products, including:

- Filtration Systems: Filtration systems are used to remove impurities, particles, and microorganisms from biopharmaceutical solutions during various stages of the production process. This includes depth filters, membrane filters, and sterile filtration systems.

- Chromatography Columns: Chromatography columns are used for the purification and separation of biomolecules based on their size, charge, and affinity. These columns contain specialized resins or stationary phases that selectively interact with target molecules, allowing for their isolation and purification.

- Single-Use Bioreactors: Single-use bioreactors are disposable vessels used for the cultivation and production of cells and microorganisms used in biopharmaceutical manufacturing. These bioreactors eliminate the need for cleaning and sterilization between batches, reducing the risk of cross-contamination and streamlining manufacturing operations.

- Tubing and Connectors: Tubing and connectors are used to transport fluids, gases, and solutions within biopharmaceutical processing systems. These components are designed to withstand the harsh chemical and mechanical conditions encountered during processing while maintaining sterility and integrity.

- Bags and Containers: Single-use bags and containers are used for the storage, transport, and handling of biopharmaceutical solutions, cell cultures, and media. These containers are sterile, disposable, and designed to maintain product quality and integrity throughout the manufacturing process.

- Mixing and Stirring Systems: Mixing and stirring systems are used to homogenize and blend biopharmaceutical solutions, ensuring uniform distribution of components and nutrients within the production vessel. These systems may include magnetic stirrers, impellers, and mixing tanks.

- Sampling and Monitoring Devices: Sampling and monitoring devices are used to collect samples and monitor critical process parameters such as pH, temperature, dissolved oxygen, and cell density during biopharmaceutical production. These devices enable real-time monitoring and control of the manufacturing process to ensure product quality and consistency.

Get Access to Free Sample Research Report with Latest Industry Insights:

https://www.prophecymarketinsights.com/market_insight/Insight/request-sample/4790

*Note: PMI Sample Report includes,

- Overview & introduction of market study

- Revenue and CAGR of market

- Drivers & Restrains factors of market

- Major key players in market

- Regional analysis of the market with a detailed graph

- Detailed segmentation in tabular form of market

- Recent development/news of market

- Opportunities & Challenges of Market

Top Leading Players in Biopharmaceutical Processing Equipment Consumables Market:

- GE Healthcare (U.S.)

- Merck KGaA (Germany)

- Thermo Fisher Scientific Inc. (U.S.)

- Danaher Corporation (U.S.)

- Sartorius AG (Germany)

- Bio-Rad Laboratories, Inc. (U.S.)

- 3M Company (U.S.)

- Repligen Corporation (U.S.)

- Agilent Technologies, Inc. (U.S.)

- Eppendorf AG(Germany)

Market Dynamics:

Driving Factors:

- The increasing demand for biopharmaceutical products, including vaccines, monoclonal antibodies, and recombinant proteins, is driving the demand for processing equipment consumables.

- Ongoing technological advancements in bioprocessing equipment and consumables, such as the development of innovative filtration membranes, chromatography resins, and single-use bioreactor systems, are enhancing process efficiency, productivity, and scalability.

- The adoption of single-use bioreactors, disposable filtration systems, and other single-use technologies is increasing in the biopharmaceutical industry due to their cost-effectiveness, flexibility, and reduced risk of cross-contamination.

- Biopharmaceutical companies and contract manufacturing organizations (CMOs) are investing in expanding and upgrading their bioprocessing infrastructure to increase production capacities, improve process efficiency, and accelerate time-to-market for biopharmaceutical products. This trend is driving the demand for advanced processing equipment and consumables.

Restrain Factors:

- Cost Considerations

- Limited Compatibility and Interoperability

Emerging Trends and Opportunities in Biopharmaceutical Processing Equipment Consumables Market:

- The adoption of single-use bioreactors, filtration systems, chromatography columns, and other processing equipment consumables is increasing due to their cost-effectiveness, flexibility, and reduced risk of cross-contamination. Manufacturers are developing innovative single-use solutions that offer enhanced performance, scalability, and ease of use.

- Advanced Filtration and Separation Technologies: There is a growing demand for advanced filtration membranes, chromatography resins, and separation technologies that enable efficient and high-yield purification of biopharmaceutical products. Manufacturers are investing in research and development to develop next-generation filtration and separation solutions with improved selectivity, throughput, and purity.

- Integration of Process Analytics and Control Systems: The integration of real-time process analytics and control systems into biopharmaceutical processing equipment consumables enables enhanced monitoring, optimization, and control of bioprocesses. Manufacturers are incorporating sensors, probes, and data analytics platforms into consumables to enable predictive maintenance, quality assurance, and process optimization.

- Customized and Modular Solutions: There is a growing demand for customized and modular biopharmaceutical processing equipment consumables that can be tailored to meet specific process requirements, product specifications, and scale-up needs. Manufacturers are offering customizable solutions that enable flexibility, modularity, and rapid deployment in bioprocessing operations.

- Focus on Sustainability and Environmental Impact: Sustainability considerations are becoming increasingly important in the design, manufacturing, and disposal of biopharmaceutical processing equipment consumables. Manufacturers are developing eco-friendly materials, recycling programs, and biodegradable alternatives to reduce the environmental footprint of consumables and promote sustainable practices across the biopharmaceutical industry.

Download PDF Brochure:

https://www.prophecymarketinsights.com/market_insight/Insight/request-pdf/4790

Challenges of Biopharmaceutical Processing Equipment Consumables Market:

- The cost of biopharmaceutical processing equipment consumables can be substantial, especially for advanced technologies and specialized products.

- Cost pressures may limit access to innovative consumables for smaller biopharmaceutical companies or those operating on tighter budgets.

- Ensuring consistent quality and performance of biopharmaceutical processing equipment consumables is critical to the safety and efficacy of biopharmaceutical products.

- Maintaining stringent quality control standards throughout the manufacturing process presents challenges, particularly for complex and customizable consumables.

Detailed Segmentation:

Biopharmaceutical Processing Equipment Consumables Market, By Product:

-

-

- Filtration

- Chromatography

- Columns

- Bioreactor

- Cell Culture

- Service

-

Biopharmaceutical Processing Equipment Consumables Market, By Application:

-

-

- Commercial

- Research

-

Biopharmaceutical Processing Equipment Consumables Market, By End User:

-

-

- Pharmaceutical

- Biotechnology

- CDMO

-

Biopharmaceutical Processing Equipment Consumables Market, By Region:

-

-

- North America

-

- U.S.

- Canada

-

- Europe

-

- Germany

- UK

- France

- Russia

- Italy

- Rest of Europe

-

- Asia Pacific

-

- China

- India

- Japan

- South Korea

- Rest of Asia Pacific

-

- Latin America

-

- Brazil

- Mexico

- Rest of Latin America

-

- Middle East & Africa

-

- GCC

- Israel

- South Africa

- Rest of Middle East & Africa

-

- North America

-

Regional Analysis:

Regional insights highlight the diverse market dynamics, regulatory landscapes, and growth drivers shaping the Biopharmaceutical Processing Equipment Consumables Market across different geographic areas. Understanding regional nuances and market trends is essential for stakeholders to capitalize on emerging opportunities and drive market expansion in the Biopharmaceutical Processing Equipment Consumables sector.

North America market is estimated to witness the fastest share over the forecast period as North American market for biopharmaceutical processing equipment consumables presents significant opportunities for suppliers and manufacturers, driven by technological innovation, regulatory compliance, strategic partnerships, and investments in R&D.

Report scope:

| Attribute | Details |

| Market Size 2024 | US$ 50.9 Billion |

| Projected Market Size 2034 | US$ 122.1 Billion |

| CAGR Growth Rate | 10.10% |

| Base year for estimation | 2023 |

| Forecast period | 2024 – 2034 |

| Market representation | Revenue in USD Million & CAGR from 2024 to 2034 |

| Market Segmentation | By Product- Filtration, Chromatography, Columns, Bioreactor, Cell Culture, Service By Application- Commercial and Research By End-User- Pharmaceutical, Biotechnology, CDMO |

| Regional scope | North America - U.S., Canada Europe - UK, Germany, Spain, France, Italy, Russia, Rest of Europe Asia Pacific - Japan, India, China, South Korea, Australia, Rest of Asia-Pacific Latin America - Brazil, Mexico, Argentina, Rest of Latin America Middle East & Africa - South Africa, Saudi Arabia, UAE, Rest of Middle East & Africa |

| Report coverage | Revenue forecast, company share, competitive landscape, growth factors, and trends |

Key highlights of the Biopharmaceutical Processing Equipment Consumables Market:

- The adoption of single-use bioreactors, filtration systems, and other processing equipment consumables is increasing due to their cost-effectiveness, flexibility, and reduced risk of cross-contamination in biopharmaceutical manufacturing.

- The biopharmaceutical processing equipment consumables market is global in scope, with manufacturers, suppliers, and end-users operating in regions around the world. Strategic partnerships, collaborations, and distribution networks facilitate access to a diverse customer base and expand market reach.

- Ensuring consistent quality and performance of processing equipment consumables is critical to the safety, efficacy, and regulatory compliance of biopharmaceutical products. Manufacturers prioritize quality assurance measures, including rigorous testing, validation, and adherence to regulatory standards.

- Sustainability considerations, including plastic waste reduction, recycling, and environmental footprint, are gaining importance in the biopharmaceutical processing equipment consumables market. Manufacturers and end-users seek eco-friendly alternatives and adopt sustainable practices to minimize environmental impact.

- Cost considerations play a significant role in the selection and adoption of processing equipment consumables, particularly for small and medium-sized biopharmaceutical companies with limited financial resources. Manufacturers strive to balance cost-effectiveness with quality, reliability, and performance in their consumable offerings.

- Managing supply chain risks, including raw material shortages, production delays, and logistics challenges, is essential to ensuring the availability and reliability of processing equipment consumables for biopharmaceutical manufacturing operations.

Any query or customization before buying:

https://www.prophecymarketinsights.com/market_insight/Insight/request-customization/4790

Explore More Insights:

- Sandhoff Disease Treatment Market - Trends, Analysis and Forecast till 2034

- EZH2 Inhibitors Market – Trends, Analysis and Forecast till 2034

- Uveal Melanoma Market - Trends, Analysis and Forecast till 2034

Blog: www.prophecyjournals.com

Follow us on:

LinkedIn | Twitter | Facebook |YouTube