Austin, Dec. 17, 2025 (GLOBE NEWSWIRE) -- Industrial Metrology Market Size & Growth Insights:

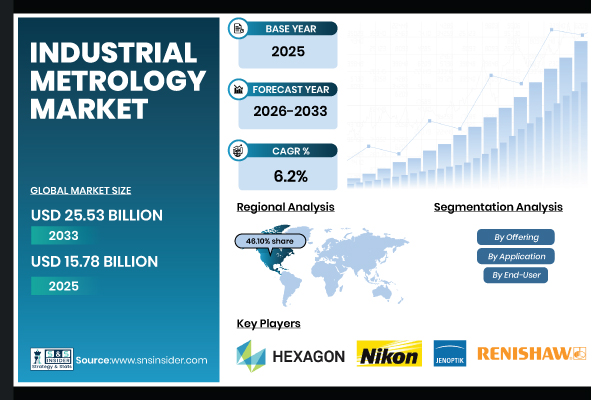

According to the SNS Insider,“The Industrial Metrology Market Size was valued at USD 15.78 billion in 2025E and is expected to reach USD 25.53 billion by 2033 and grow at a CAGR of 6.2% over 2026-2033.”

Growing Emphasis on Quality Control to Meet the Industry Standards to Augment Market Expansion Globally

The complexity of contemporary production processes is rising as quality and safety become more important considerations. Because of this, effective quality control is necessary in modern production to guarantee process efficiency. In this sense, industrial metrology is the framework that makes it possible to measure precisely using the right instruments and techniques. It helps identify issues and get rid of them in the early stages of manufacturing since it gives manufacturers a clear picture of how much a product falls short of the criteria.

Get a Sample Report of Industrial Metrology Market Forecast @ https://www.snsinsider.com/sample-request/3714

Leading Market Players with their Product Listed in this Report are:

- Hexagon

- Nikon

- FARO Technologies

- Carl Zeiss

- Jenoptik

- KLA Corporation

- Renishaw

- Mitutoyo Corporation

- KEYENCE CORPORATION

- Creaform

- Perceptron

- Automated Precision Inc.

- Applied Materials Inc.

- AccuScan

- CARMAR Accuracy

- Baker Hughes

- Cyberoptics

- Cairhill

- ATT Metrology

- Trimet

Industrial Metrology Market Report Scope:

| Report Attributes | Details |

| Market Size in 2025 | USD 15.78 Billion |

| Market Size by 2033 | USD 25.53 Billion |

| CAGR | CAGR of 6.2% From 2026 to 2033 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segmentation | • By Offering (Hardware, Software, Services) • By Equipment (Coordinate Measuring Machine (CMM), Optical Digitizer and Scanner (ODS), Measuring Instruments, X-ray and Computed Tomography, Automated Optical Inspection, Form Measurement Equipment, 2D Equipment) • By Application (Quality Control & Inspection, Reverse Engineering, Mapping and Modelling, Others) • By End-User (Aerospace & Defense, Automotive, Semiconductor, Manufacturing, Others) |

Purchase Single User PDF of Industrial Metrology Market Report (20% Discount) @ https://www.snsinsider.com/checkout/3714

Complexity of Technology and Limited Technical Knowledge for Integration May Hinder Expansion

As both coordinate measuring systems and optical scanning systems often produce a lot of data, integrating industrial metrology systems with the current manufacturing infrastructure and software systems can be very difficult. Companies need data management competence to guarantee that it is seamlessly incorporated into the current data platform and does not create data silos. However, when combining metrology equipment with various industrial software or hardware systems, compatibility problems could occur.

Key Industry Segmentation Analysis

By Offering

The hardware segment is continuously rising with a market share of more than 46.76% in 2025E. Hardware, such as coordinate measuring machines, optical digitizers and scanners, and X-ray and computed tomography systems provide increased precision and accuracy in surface separations, which enhances the quality of a product.

By Application

The quality control & inspection segment became the dominant segment with a market share of around 40.16% in the Industrial Metrology Market in 2025E. Due to the need to increase production and achieve precision, the demand for high-precision metrology and inline inspection has expanded over numerous industries.

By End-User

The automotive segment is a dominating segment with a market share of more than 49.56% in 2025E as automotive makers are using 3D technologies and optical inspection methods. Production groups scan a part or sub-assembly and receive an accurate picture of the source of quality concerns with 3D measuring technologies, making it very beneficial to the automotive industry.

Regional Insights:

The North American industrial metrology market has dominated in 2025E with a market share of around 46.10%. There is an increase in the demand for automation through consistent and long-term application of industrial metrology in the North American region. In the Asia Pacific region, there is an increasing adoption and application of industrial metrology. The first reason is the high rate of industrialization and manufacturing growth in major producers of manufacturing products mainly in China, India, Japan, South Korea, and Taiwan.

Do you have any specific queries or need any customized research on Industrial Metrology Market? Submit your inquiry here @ https://www.snsinsider.com/enquiry/3714

Recent Developments:

- In April 2024, Cognex Corporation developed the In-Sight L38 3D Vision Systems. This system is dependent on the combination of AI, 2D, and 3D vision technologies. One of the most important advantages of this system is enhanced training. Another advantage of the In-Sight L38 3D Vision System is that it offers reliable solutions for inspection and measurements due to the inclusion of AI for the identification of features and 3D measurement based on a rule.

- In March 2024, Hexagon’s Manufacturing Intelligence division developed the SmartScan VR800, a high-productivity structured light scanner. The main advantage associated with this system is that it is fitted with a motorized zoom lens. This lens may be adjusted to provide data with different degrees of resolution and cover a larger part of an item to be measured.

Exclusive Sections of the Industrial Metrology Market Report (The USPs):

- PERFORMANCE & MEASUREMENT ACCURACY METRICS – helps you benchmark precision levels across CMM, optical, 3D scanning, and X-ray systems, along with inspection speed across key industries.

- AUTOMATION PENETRATION IN QUALITY INSPECTION – helps you understand the shift from manual to automated metrology, highlighting productivity gains, consistency improvements, and labor efficiency trends.

- INDUSTRY-WISE ADOPTION & DEPLOYMENT TRENDS – helps you analyze adoption intensity across automotive, aerospace, and general manufacturing, including the average number of systems per facility.

- DIGITAL & SMART MANUFACTURING INTEGRATION – helps you assess the integration of metrology with CAD/CAM, digital twins, IoT, and AI-enabled predictive analytics for real-time quality control.

- IN-LINE & REAL-TIME METROLOGY ADOPTION RATE – helps you identify opportunities in in-line inspection solutions that reduce inspection time and support high-throughput production environments.

- COST STRUCTURE & ROI BENCHMARKS – helps you compare system costs by technology type, spending split across hardware, software, and services, and expected payback periods for metrology investments.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.