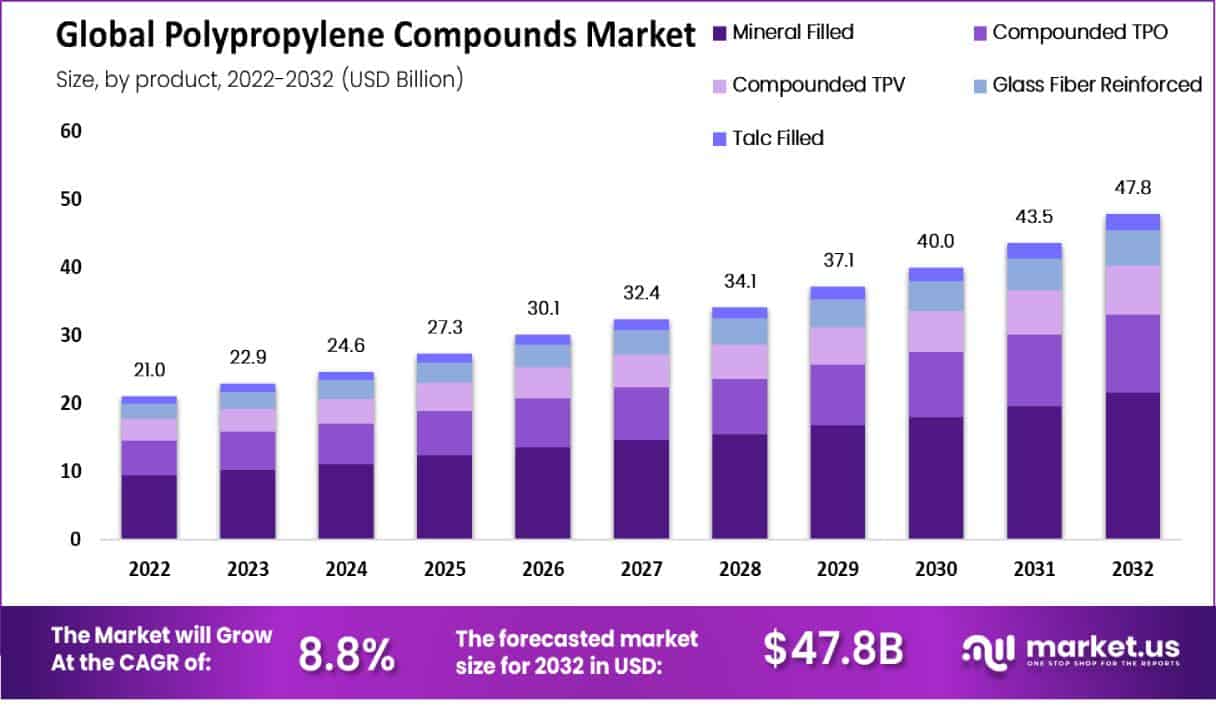

New York, April 28, 2023 (GLOBE NEWSWIRE) -- The Polypropylene Compounds Market is projected to grow at a CAGR of 8.8%, with its worth expected to increase from USD 21.0 billion in 2022 to approximately USD 47.8 Bn by 2032.

Polypropylene is a type of thermoplastic polymer with exceptional characteristics like high stiffness, strong impact resistance, and minimal moisture absorption is polypropylene compounds. To improve their performance for particular uses, polypropylene resin is combined with other additives like glass fibers, talc, or calcium carbonate to make polypropylene compounds.

Get additional highlights on major revenue-generating segments, Request a Polypropylene Compounds Market sample report at https://market.us/report/polypropylene-compounds-market/request-sample/

Key Takeaway:

- By product, the mineral-filled product segment is dominant due to it gives improved stiffness, dimensional stability, and heat resistance compared to unfilled polypropylene.

- By type, the market is dominated by homo polymers.

- By end-users, the automotive industry is a major contributor to the polypropylene compounds market.

- In 2022, based on region, the Asia Pacific region is dominant with a market share of 46%.

- APAC is growing at a higher rate owing to rapid industrialization, a growing population, and expanding middle class.

Factors affecting the growth of the Polypropylene Compounds Industry

There is a number of factors that have an impact on the growth of the polypropylene compounds industry. Some of these factors include:

- Increasing Demand: As demand for polypropylene compounds grows, the industry will experience expansion.

- Technological Developments: Technological advances could make it simpler to manufacture polypropylene composites, boost their quality, and lower cost. This might improve the effectiveness and viability of the sector.

- Raw Material Availability: Polypropylene compounds are made from polypropylene resin, which is extracted from crude oil. The price and availability of crude oil can significantly impact the growth of this industry.

- Government Regulations: Regulations and policies related to environmental protection, labor laws, and trade agreements can have an impact on the industry's growth. For instance, regulations for recycling and waste management may increase demand for recycled polypropylene compounds.

- Economic Factors: The success of a business can be affected by factors like interest rates, inflation rates, and currency exchange rates. For instance, a strong currency raises the cost of exports, which lowers demand and slows development.

To understand how our report can bring a difference to your business strategy, Inquire about a brochure at https://market.us/report/polypropylene-compounds-market/#inquiry

Top Trends in Polypropylene Compounds Market

The polypropylene compound market experienced significant growth over the past several years & it is expected that the market will continue to grow in the future. Polypropylene offers various benefits which include high impact resistance, chemical resistant, and low moisture absorbency which makes it an attractive choice for manufacturers. The increasing trend for sustainable & eco-friendly goods has also led to the development and use of bio-based polypropylene & recycled polypropylene which further drives the market's growth. The market is also faced with challenges like fluctuating prices of raw materials & the emergence of alternative materials.

Market Growth

In the industries such as packaging, consumer goods, construction, and automotive there is a wide range of applications for polypropylene compounds. The market is growing because of the rise in demand for lightweight materials in the automotive industry, and in the packaging industry, the use is increased. Polypropylene compounds are eco-friendly and sustainable materials hence they have high demand in upcoming years. They are also recyclable and have minimum carbon footprints than any other materials. In the regions, the Asia-Pacific will be the largest market because of rapid industrialization and growing demand from end-use industries.

Regional Analysis

The global polypropylene compounds market can be analyzed regionally to gain insights into its growth and potential. Asia-Pacific is the largest market with a revenue share of 46% for polypropylene compounds, with China and India being the major contributors to growth. The drivers for growth in this region are rapid industrialization, a growing population, and expanding middle class. These drivers help in increasing demand for industries such as packaging, construction, and automotive.

Europe and North America are also significant regions for the polypropylene market. Germany and the United States are major contributors with significant market share. The demand for polypropylene compounds in these regions is driven by the increasing focus on sustainability and the use of lightweight materials in various applications. Africa, the Middle East, and Latin America are emerging regions for polypropylene compounds & the demand in this region is driven by the rise of various industries like packaging & automotive.

Have Queries? Speak to an expert or Click Here To Download/Request a Sample

Scope of the Report

| Report Attribute | Details |

| Market Value (2022) | USD 21.0 billion |

| Market Size (2032) | USD 47.8 billion |

| CAGR (from 2023 to 2032) | 8.8% |

| Asia-Pacific Revenue Share | 46.0% |

| Historic Period | 2016 to 2022 |

| Base Year | 2022 |

| Forecast Year | 2023 to 2032 |

Market Drivers

Polypropylene compounds are lighter than many traditional materials such as metal and glass, yet offer high strength and durability. As a result, they're increasingly being utilized in the automotive and construction industries to reduce weight and boost fuel efficiency.

High demand for polypropylene compounds is from the packaging industry, because of their properties like moisture resistance, superior barrier property, and heat resistance. With an increasing demand for food and beverage packaging - particularly in developing countries - polypropylene compounds market size is expected to expand significantly over the coming years.

Market Restraints

Environmental issues like plastic made by petroleum, and polypropylene, can have a negative effect on the ecosystem when it is produced. Demand for environmentally friendly substitutes may rise as consumers become more conscious of the negative effects of plastic. Prices for the feedstocks that go into making polypropylene, such as crude oil and natural gas, can fluctuate wildly. This might lead to price volatility in the market for polypropylene compounds.

Market Opportunities

The market for polypropylene compounds presents many chances for development and invention. One such chance results from the expanding need for strong yet lightweight materials in sectors like building, packaging, and automotive. Polypropylene compounds are ideal for lightweight automotive parts, packaging materials, and building uses due to their superior mechanical properties.

The creation of bio-based and environmentally friendly polypropylene compounds represents another possible market opportunity. Sustainable alternatives to conventional plastics are in greater demand as customers become more environmentally conscious. This need can be satisfied while providing consumers with a more environmentally friendly choice thanks to bio-based polypropylene compounds produced from renewable resources like biomass or agricultural waste.

Grow your profit margin with Market.us - Purchase This Premium Report at https://market.us/purchase-report/?report_id=100810

Report Segmentation of the Polypropylene Compounds Market

Product Insight

With a 46% market share, the mineral-filled product segment dominates the industry. Mineral-filled polypropylene composites are made by mixing polypropylene resin with minerals like talc, calcium carbonate, and glass fibers. Compared to unfilled polypropylene, these composites have better heat resilience, dimensional stability, and stiffness. Polypropylene and EPDM (ethylene-propylene-diene monomer) are the main ingredients in compound TPO rubber. Compound TPO is ideal for automotive and construction applications due to its exceptional impact resistance, low-temperature flexibility, and weather ability.

Type Insight

The industry is dominated by homo polymers. Propylene monomer is used to create homo polymers, which have good stiffness, heat resistance, and chemical resistance. By copolymerizing propylene monomer with a small amount of ethylene monomer to generate an even distribution along the chain, random copolymers can be made. When homo polymers are combined with an elastic polymer like ethylene-propylene rubber (EPR) or (EPDM) ethylene-propylene-diene monomer, impact copolymers are produced.

End User Insight

The automotive sector is the primary end-user of polypropylene compounds. These plastics can be used to create parts for internal and exterior components like bumper fascia, instrument panels, and door trims. Because polypropylene compounds have great electrical properties like strong insulation resistance and low dielectric constant, they are also useful in electrical and electronic applications. Furthermore, because of their superior stiffness, toughness, and barrier qualities, polypropylene compounds are used in packing such as containers, cap closures, and films.

Recent Development of the Polypropylene Compounds Market

- In February 2021, LyondellBasell Industries Holdings B.V. unveiled the development of a new polypropylene compound specifically tailored for automotive applications - called Purell RP320M - that provides improved dimensional stability and reduced warpage.

- In December 2020, ExxonMobil Corporation revealed the development of Exxtral BMU138, a polypropylene compound for use in automotive parts production. This material is engineered to offer improved impact resistance and stiffness properties.

For more insights on the historical and Forecast market data from 2016 to 2032 - download a sample report at https://market.us/report/polypropylene-compounds-market/request-sample/

Market Segmentation

Based on Product

- Mineral Filled

- Compounded TPO

- Compounded TPV

- Glass Fibre Reinforced

- Talc Filled

Based on Type

- Homo Polymers

- Random Copolymers

- Impact Copolymers

Based on End-User

- Automotive

- Electricals and Electronics

- Packaging

- Building and Construction

- Textiles

- Other End-users

By Geography

- North America

-

- The US

- Canada

- Mexico

- Western Europe

-

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

- Eastern Europe

-

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

-

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

- Middle East & Africa

-

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Competitive Landscape

The global polypropylene compounds market is highly competitive and fragmented, with several key players operating within it. Companies invest in product innovation, strategic partnerships, and mergers/acquisitions to maintain their position and expand globally. Furthermore, demand for polypropylene compounds is expected to increase due to their increasing applications across various end-use industries such as automotive, packaging, construction, electrical & electronics - also driven by growing interest in lightweight materials that offer improved fuel efficiency & reduce carbon emissions.

Some of the major players include:

- LyondellBasell Industries Holdings B V

- Solvay

- ExxonMobil Corp

- Trinseo

- Sumitomo Chemical Co Ltd

- Washington Penn Plastics Co Ltd

- Rhetech Inc

- A Schulman

- Avient Corp

- Repsol

- SABIC

- PolyOne

- Specialty Chemicals and Polymers

- Peeco Polytech Private Limited

- Plastochem India

- Other Key Players

Browse More Related Reports:

- Expanded Polypropylene Foam Market was valued at USD 1,186.6 million in 2022 and is expected to reach USD 2581.9 million in 2032. This market is estimated to register a CAGR of 8.3% between 2023 and 2032.

- Extruded polypropylene foam market was valued at USD 847.4 million in 2022 and is expected to grow at a CAGR of 6.2%

- Ethylene Copolymers Market was worth USD 45,439.3 million in 2021. It is projected to grow at a CAGR of 3.7%, between 2023 and 2032.

- Smart Packaging Market was valued at USD 28.7 billion in 2022 and is expected to reach at USD 52.1 billion in 2032. Between 2023 and 2032, this market is estimated to register the highest CAGR of 6.3%.

- Chelating Agents Market was valued at USD 6.09 billion in 2022 and is expected to reach around USD 9.17 billion by 2032. Between 2023 and 2032, this market is estimated to register a CAGR of 4.29%.

About Us:

Market.US (Powered by Prudour Pvt Ltd) specializes in in-depth market research and analysis and has been proving its mettle as a consulting and customized market research company, apart from being a much sought-after syndicated market research report-providing firm. Market.US provides customization to suit any specific or unique requirement and tailor-makes reports as per request. We go beyond boundaries to take analytics, analysis, study, and outlook to newer heights and broader horizons.

Follow Us On LinkedIn Facebook Twitter

Our Blog: