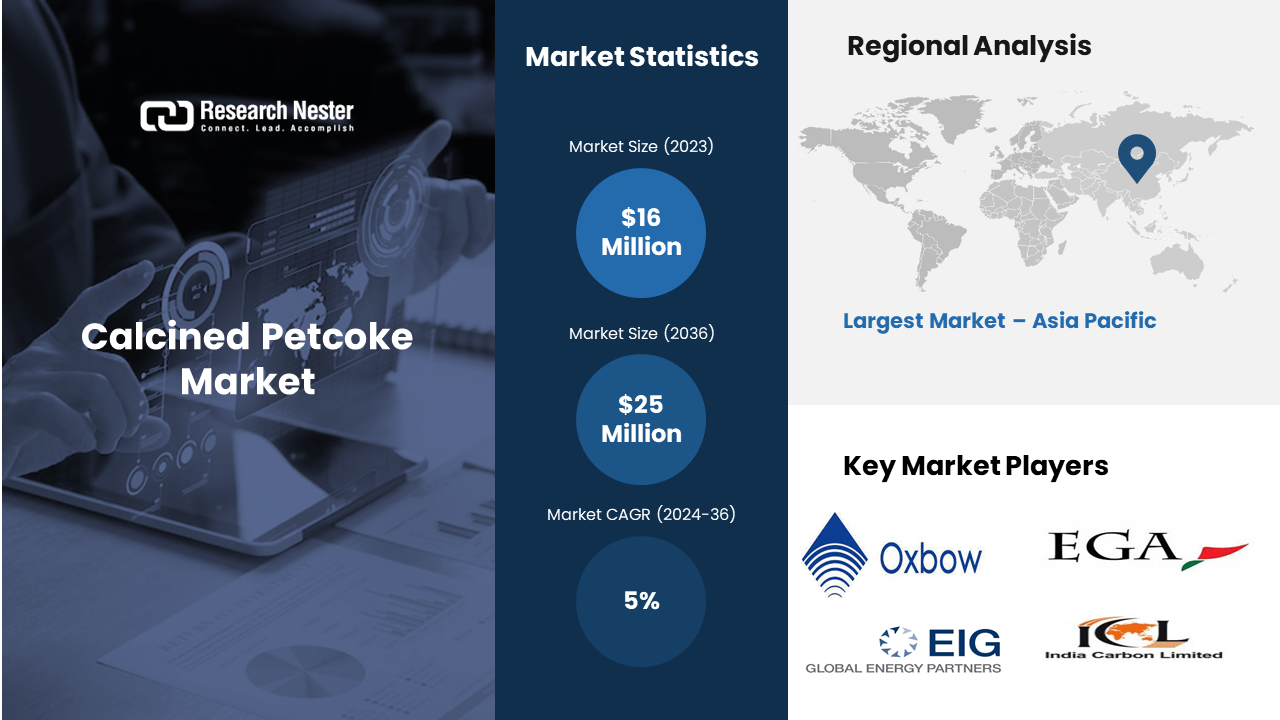

New York , March 13, 2024 (GLOBE NEWSWIRE) -- The global calcined petcoke market size is predicted to expand at 5% CAGR between 2024 and 2036. The market is projected to garner a revenue of USD 25 billion by the end of 2036, up from a revenue of USD 16 billion in the year 2023. The reason behind the growth is due to the growing production of crude oil across the globe. The most in-demand commodity in the world right now is crude oil which is one of the main factors propelling the world economy. For instance, the demand for crude oil worldwide was over 99 million barrels per day in 2022 and is expected to rise to around 101 million barrels per day in 2023. According to estimates, global crude oil output rose at a record of over 5% rate in 2022, significantly faster than it did in 2021.

Request Free Sample Copy of this Report @ https://www.researchnester.com/sample-request-5520

The growing government initiatives to create a green environment are believed to fuel the calcined petcoke market growth. To support the transformation of energy and industrial systems, increase energy efficiency, and combat environmental pollution, governments across the globe have agreed upon general principles that will guide the implementation of the green economy at all levels. Furthermore, governments are enacting stricter laws, and green levies on activities that negatively impact the environment, and are also providing grants and subsidies to create game-changing technologies including waste management, carbon capture, renewable energy, and energy efficiency.

Calcined Petcoke Market: Key Takeaways

- Market in Asia Pacific to propel highest growth

- The anode segment to garner the highest growth

- Market in North America to grow at the highest rate

Increasing Adoption of Calcined Petcoke in the Metal Industry across the Globe to Boost Market Growth

Calcined petroleum coke is mostly used in metallurgy and foundries to melt aluminum for use in manufacturing special high-carbon steel, as a carbon raiser in foundries to make carbon and to manufacture a variety of carbon and graphite products. Petroleum coke is extensively used as fuel in power plants to produce electricity. For instance, more than 75% of Petcoke generated globally is classified as fuel-grade thus, it is employed in the production of electricity. Calcined Petcoke is an electrically conductive substance that can be combined with carbon fiber as an additive to create an electrically conductive cement mortar that is utilized as an energy source in the cement industry. For instance, more than 78% of fuels used in cement kilns globally are conventional fossil fuels, with petcoke making up over 40% of this total. Petcoke is used as a feedstock in the manufacture of diverse carbon goods, including carbon brushes, graphite electrodes, and more carbon products. Moreover, it goes toward making activated carbon, which is used to purify air and water and it is utilized in the creation of paints, inks, and polymers.

Calcined Petcoke Industry: Regional Overview

The global calcined petcoke market is segmented into five major regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa region.

Expansion of Aluminum Smelting Capacity to Drive the Market Growth in Asia Pacific Region

The calcined petcoke market in the Asia Pacific region is estimated to garner the largest revenue by the end of 2036. Increased aluminum smelting capacity indicates a growing demand for calcined petcoke as a crucial component in the production of carbon anodes. This growth driver is closely tied to the overall economic development and industrialization in the region. The Asia Pacific region is expected to witness a 20% increase in aluminum smelting capacity by 2030, driven by rising demand in sectors like automotive and construction. Modernization efforts in the steel industry often involve the adoption of advanced technologies and materials. Calcined petcoke, with its high carbon content, becomes essential in the manufacturing of steel electrodes, contributing to increased efficiency. Calcined petcoke can find applications in renewable energy projects, particularly in the production of electrodes for certain types of energy-intensive processes. The emphasis on reducing carbon emissions aligns with the properties of calcined petcoke. Stringent emission standards drive industries to adopt cleaner and more efficient technologies. Calcined petcoke, with its potential for reducing emissions in certain applications, may experience increased demand due to regulatory compliance.

Growing Steel Industry Investments to Propel Growth in the North America Region

The North American calcined petcoke market is estimated to garner the highest CAGR by the end of 2036. Modernization efforts in the steel industry often involve the adoption of advanced materials like calcined petcoke. The higher efficiency in steel production contributes to increased demand for calcined petcoke as a raw material for steel electrodes. North American steel manufacturers plan to invest USD 3 billion in upgrading and expanding their facilities, resulting in a 20% increase in steel production efficiency by 2024. Increased aluminum production capacity indicates a higher demand for calcined petcoke, a key ingredient in carbon anodes essential for aluminum smelting. The growth of these sectors is closely tied to economic development and industrial activities. Modernization efforts in the steel industry often involve the adoption of advanced materials like calcined petcoke. The higher efficiency in steel production contributes to increased demand for calcined petcoke as a raw material for steel electrodes. Calcined petcoke, with its potential applications in certain renewable energy processes, could see increased demand as the region focuses on cleaner energy solutions.

Make an Inquiry Before Buying this Report @ https://www.researchnester.com/inquiries-before-buying-5520

Calcined Petcoke Segmentation by Grade

- Anode

- Needle

The anode segment in global calcined petcoke market is anticipated to hold the largest share during the forecast period. Anode-grade pet coke also known as raw pet coke (RPC) or green pet coke (GPC) is low in metals and sulfur and needs to be calcined before being baked into anodes. For instance, Anode-grade petcoke is usually a green, calcinable petcoke with over 2% sulfur, little ash, and very little metal content. Calcined petcoke (CPC) is created by heating anode-grade petcoke below its melting point to remove moisture and volatile materials therefore it has low metal concentration and is a product of low quality that contains a lot of carbon. Moreover, the majority of anode-grade petroleum coke has relatively few contaminants, as a result of which it burns cleaner than other fuels and has good abrasion resistance. As the electric vehicle market expands, the demand for high-performance anodes, particularly those based on materials like graphite, is expected to surge. Graphite anodes are critical components in lithium-ion batteries, and the growth of the EV market directly influences the anode segment. Anodes play a vital role in energy storage systems, especially in lithium-ion batteries used for renewable energy storage. As the demand for renewable energy storage solutions rises, so does the demand for high-quality anodes.

Calcined Petcoke Segmentation by End-User

- Carburizing & Recarburizing

- Electric Arc & Induction Furnaces

The electric arc & induction furnaces segment in the global calcined petcoke market is anticipated to hold a significant share during the forecast period. Calcined petroleum coke is a high-purity solid carbonaceous material that is used to make electrodes utilized in the construction of electric and induction furnaces. For instance, the calcined pet coke used to make graphite electrodes is made in a forging smelting furnace at a temperature of over 1400°C, with a carbon content of roughly 98%. Moreover, an electrode is an apparatus to carry electricity into an electric arc furnace and is primarily used for the steel production process. Additionally, electric arc furnaces are primarily used to melt or extract ferrous or non-ferrous metals and can also be used to smelt steels, such as special tool steel, aviation steel, stainless steel, and others, as they require tight chemical composition and good mechanical performance. Furthermore, petroleum coke that has been calcined is frequently used in the carburizing and recarburizing process to balance the carbon level when making steel as it has higher carbon content and lower grade of coke.

Calcined Petcoke Segmentation by Application

- Aluminum

- TiO2

- Steel

- Paint & Coatings

- Fertilizers

- Metals

Few of the well-known market leaders in the global calcined petcoke market that are profiled by Research Nester are Rain Industries Limited, NingXia Wanboda Carbons and Graphite, India Carbon Limited, Weifang Lianxing New Material Technology Co., Ltd., Aluminium Bahrain, Oxbow Corporation, Shandong Zhongyang New Material Technology Co., LTD, and other key market players.

Recent Development in the Calcined Petcoke Market

- Emirates Global Aluminium (EGA) partnered with British oil and gas firm BP p.l.c. to find and create ways to lower the amount of carbon dioxide produced and optimize the quality and emissions of the calcined petroleum coke it obtains from different suppliers.

- EIG Global Energy Partners together with Novonor and Brazilian Development Bank (BNDES) acquired Ocyan Participações (Ocyan), a Brazilian oil and gas solutions provider to create new opportunities and lead Ocyan into a new stage of development.

Read our insightful Blogs and Data-driven Case Studies:

- Guarding of Water Treatment Chemicals: A careful approach for Sustainability

Discover the importance of safeguarding your water treatment chemicals and save the environment through methods. Gain insights into the risks related to these substances and uncover effective methods to lower their use.

- Top Chemical Manufacturer emerged a Winner by Analyzing its Competitive Landscape and Restructuring its Benchmarking Exercise

Know by with the help of Research Nester product portfolio analysis, a company in chemical industry gained insight of preferences & demand in the Indian market. By considering our suggestions, they were able to reach a growth of 45% by 2022.

About Research Nester

Research Nester is a one-stop service provider with a client base in more than 50 countries, leading in strategic market research and consulting with an unbiased and unparalleled approach to helping global industrial players, conglomerates, and executives for their future investment while avoiding forthcoming uncertainties. With an out-of-the-box mindset to produce statistical and analytical market research reports, we provide strategic consulting so that our clients can make wise business decisions with clarity while strategizing and planning for their forthcoming needs and succeed in achieving their future endeavors. We believe every business can expand to its new horizon, provided the right guidance at the right time is available through strategic minds.