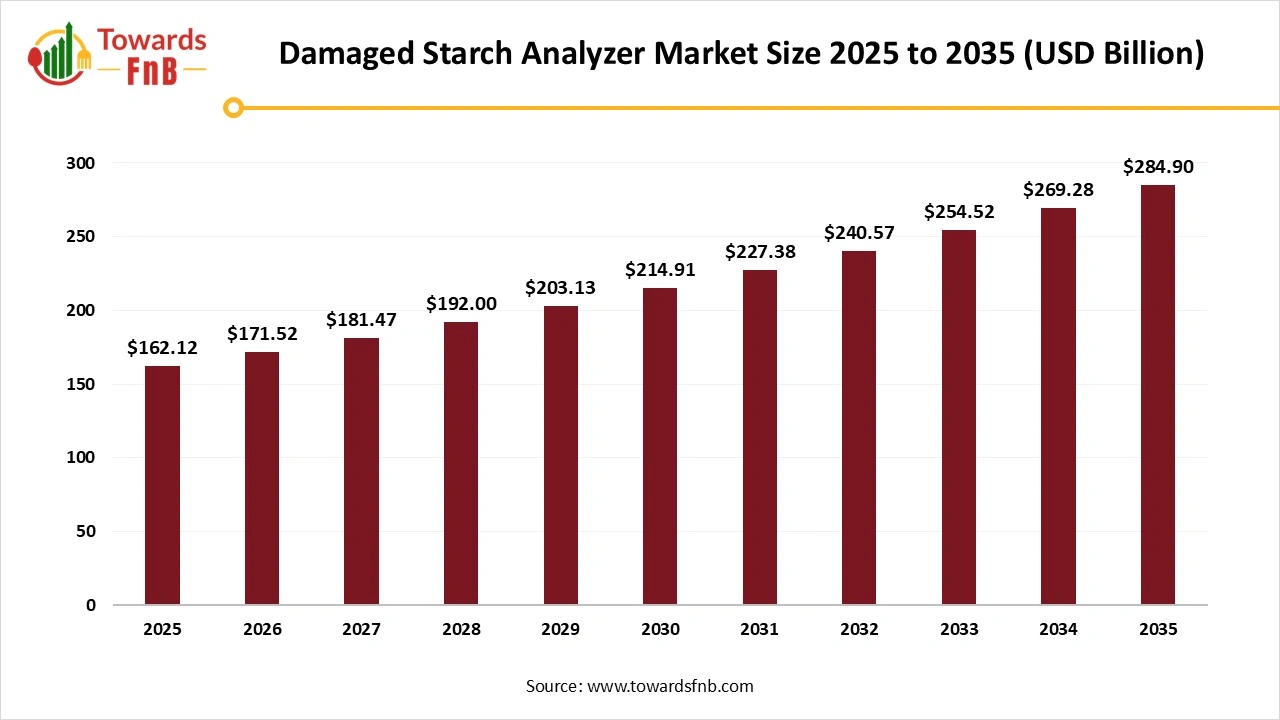

Ottawa, Dec. 17, 2025 (GLOBE NEWSWIRE) -- The global damaged starch analyzer market size stood at USD 162.12 billion in 2025, indicating a steady upward trajectory as analytical testing solutions gain wider adoption. A study published by Towards FnB, a sister firm of Precedence Research, highlights the market’s expansion across laboratory-based, in-line, and integrated flour quality-control systems deployed by mills, bakeries, and food manufacturers worldwide.

Market growth is being driven by the rising demand for consistent product quality in the food and beverage sector, particularly in bakery, snack, and cereal manufacturing, where damaged starch levels directly affect water absorption, dough performance, and final product texture. The increasing emphasis on precision flour-quality control, automation, and advanced analytical instrumentation is further accelerating adoption, as producers seek to reduce variability, optimize yield, and meet stringent quality specifications.

Note: This report is readily available for immediate delivery. We can review it with you in a meeting to ensure data reliability and quality for decision-making.

Access the Full Study Instantly | Download Sample Pages of the Report Now@ https://www.towardsfnb.com/download-sample/5958

Key Highlights of the Damaged Starch Analyzer Market

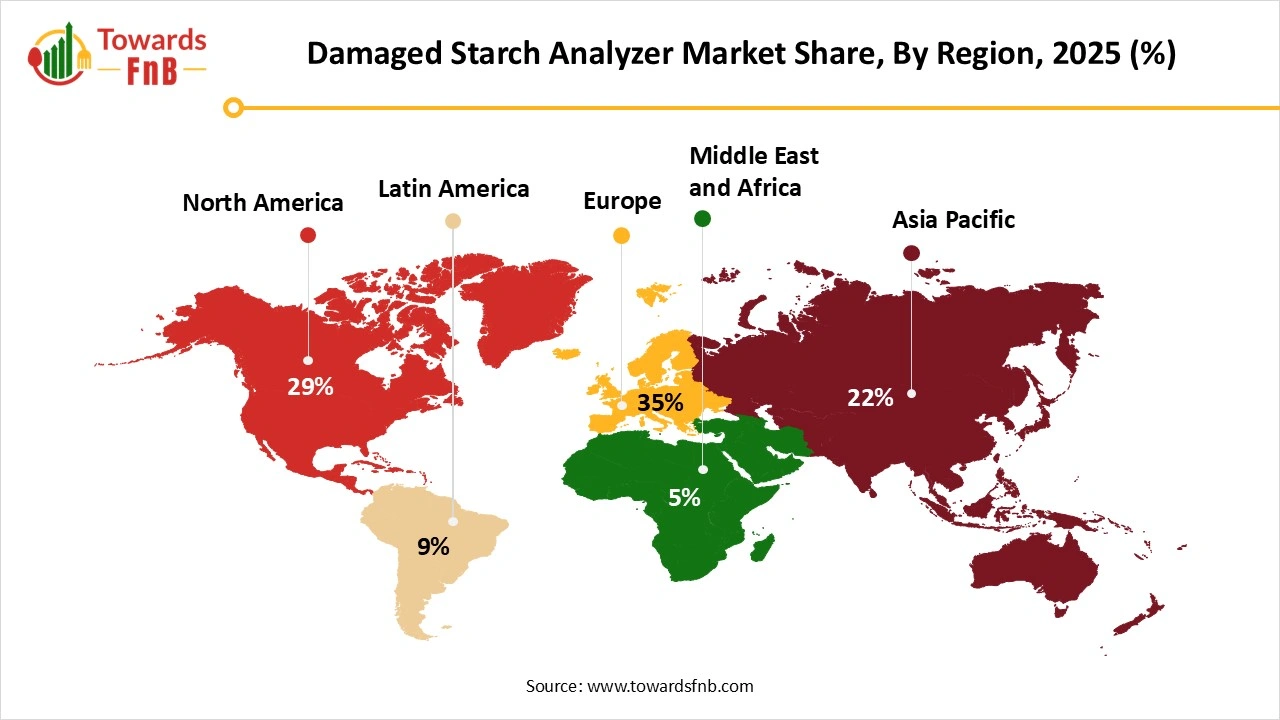

- By region, Europe led the damaged starch analyzer market with a 35% share of revenue in 2025, while the Asia Pacific region is expected to experience the fastest growth during the forecast period.

- By technology, the enzymatic-based analyzers segment held a significant market share in 2025, whereas the NIR analyzers segment is projected to grow at the fastest CAGR between 2026 and 2035.

- By product, the benchtop analyzer segment held the largest market share in 2025, while the portable/handheld segment is expected to see the fastest growth rate during the forecast period from 2026 to 2035.

- By application, the flour milling quality control segment dominated the market in 2025, while the baking and ingredient manufacturing segment is anticipated to grow at the fastest CAGR from 2026 to 2035.

“Damaged starch measurement has evolved from a laboratory reference test into a strategic operational tool,” said Vidyesh Swar, Principal Consultant at Towards FnB. “AI-enabled and in-line analyzers are allowing millers and bakeries to make faster, more consistent decisions reducing waste, improving yield, and meeting increasingly strict quality specifications.”

Higher Demand for Enhanced Product Quality is a Major Factor for the Growth of the Damaged Starch Analyzer Industry

The damaged starch analyzer market is observed to grow due to higher demand for quality control in the food and beverages and baking industries. The market is also observed to increase due to the higher use of analytical tools to maintain the precise quality of flour during baking and the preparation of various other food options. Maintaining flour quality while baking, flour milling, dough handling, and water absorption is another major factor for the market’s growth.

Technological advancements and food safety regulations are other major factors driving the market's growth. The market is also observed to grow due to rising investment in advanced analytics for grain and flour management, higher food consumption, increasing technological advancements, and higher demand for enhanced quality control.

Technological Advancements are helpful for the Growth of the Market

Technological advancements help the industry flourish by focusing on improved user experience, AI integration, speed, automation, and the use of simpler, faster, enzyme-free tools. Such tools help analyze starch damage with ease and enhance flour quality control and milling operations in the baking, food, and beverage industries by using real-time data. Such advanced factors collectively help fuel the market's growth.

Artificial intelligence (AI) is influencing the damaged starch analyzer market by improving measurement accuracy, accelerating analysis, and expanding its relevance across the milling, baking, and cereal processing industries. Damaged starch levels are critical to flour functionality, water absorption, dough rheology, and finished product quality, and AI is helping move analysis from manual interpretation toward more automated, consistent decision-making.

In instrument design and operation, AI models are integrated with enzymatic and spectroscopic measurement systems to improve signal interpretation. Machine learning algorithms analyze response curves from amylase activity, glucose release, or near-infrared spectroscopy to distinguish true starch damage from noise caused by moisture variation, protein interference, or particle-size differences. This improves repeatability and reduces operator-dependent variability, which is a key limitation in traditional damaged starch testing.

New Trends of the Damaged Starch Analyzer Market

- Higher demand for products with consistent starch quality, in turn, drives increased demand for analyzers, a major factor in market growth.

- Higher demand for technologically advanced, faster, and user-friendly analyzers and other equipment is another vital factor for the market’s growth.

- The expanding use of analyzers across domains such as pharmaceuticals, textiles, and the paper industry also fuels the market's growth.

View Full Market Intelligence@ https://www.towardsfnb.com/insights/damaged-starch-analyzer-market

Case Study Snapshot: Industrial Milling Quality Optimization (2024–2025)

Industry: Wheat Flour Milling

Region: Europe

Challenge: Despite consistent protein levels, a large industrial mill faced variability in dough hydration, fermentation performance, and bread volume reported by commercial bakery clients.

Solution: The mill deployed automated damaged starch analyzers combining enzymatic and NIR-based measurement at incoming grain inspection and post-milling quality control stages. Real-time starch damage data was used to fine-tune roller pressure and milling intensity.

Results:

- 12% reduction in water-absorption variability

- ~18% decrease in batch rejections

- Improved dough handling consistency and fewer customer complaints within six months

Strategic Impact:

This case highlights how modern damaged starch analyzers enable proactive process control, helping millers optimize yield, reduce waste, and consistently meet bakery specifications—positioning starch damage as a critical quality metric in industrial food production.

Product Survey of the Damaged Starch Analyzer Market

| Product Category | Description or Function | Measurement Method or Technology | Key Applications or End Use Segments | Representative Manufacturers or Systems |

| Enzymatic Damaged Starch Analyzers | Instruments that quantify damaged starch content based on enzymatic hydrolysis and glucose release. | Amylase enzymatic assay, spectrophotometric glucose measurement | Flour milling QC, bakery ingredient testing, cereal science labs | Chopin Technologies SDmatic, Megazyme assay systems |

| Amperometric Damaged Starch Analyzers | Automated systems measuring electrical current generated during enzymatic starch breakdown. | Amperometric glucose detection | Industrial flour mills, high-throughput QC labs | Chopin SDmatic 2 |

| Manual Damaged Starch Test Kits | Reagent-based kits for laboratory determination of starch damage. | Enzymatic colorimetric assays | Academic research, small milling labs | Megazyme Damaged Starch Assay Kits |

| Near Infrared (NIR) Based Starch Damage Estimation Systems | Non-destructive estimation of damaged starch using calibrated NIR models. | Near infrared spectroscopy with chemometric models | Rapid in-line flour analysis, large mills | Bruker NIR analyzers, Foss NIR Systems |

| Automated Flour Quality Analyzers with Starch Damage Modules | Multi-parameter analyzers incorporating damaged starch into flour quality profiling. | Enzymatic plus rheological integration | Integrated flour QC labs | Chopin Mixolab with starch damage correlation |

| Benchtop Laboratory Damaged Starch Analyzers | Compact analyzers designed for routine laboratory testing. | Enzymatic amperometric detection | Research labs, quality control labs | Chopin SDmatic compact systems |

| In-Line Starch Damage Monitoring Systems | Process-integrated systems for estimating starch damage during milling. | NIR inline sensors, process analytics | Industrial wheat and corn mills | Foss In-Line NIR, Buhler process analytics |

| Damaged Starch Analyzers for Wheat Flour | Systems calibrated specifically for wheat-flour starch-damage ranges. | Wheat-specific enzymatic calibration | Bread flour production, bakery ingredient QC | Chopin Technologies, wheat lab equipment suppliers |

| Damaged Starch Analyzers for Corn and Rice Flour | Analyzers adapted for non-wheat cereal starch matrices. | Multi-enzyme assay systems | Gluten-free flour production, cereal processing | Megazyme, NIR-based cereal systems |

| Research Grade Starch Damage Analysis Systems | High precision instruments for academic and applied cereal science research. | Enzymatic reference methods, spectrophotometry | Universities, cereal research institutes | Megazyme reference assays, research lab platforms |

| Quality Control Starch Damage Systems for Bakeries | Instruments used to optimize water absorption and dough performance. | Rapid enzymatic methods | Industrial bakeries, premix producers | Chopin SDmatic used in bakery QC labs |

| Starch Damage Analyzers for Milling Process Optimization | Tools used to correlate milling intensity with starch damage. | Process analytics with starch damage readouts | Wheat milling optimization | Buhler milling labs, Chopin solutions |

| Portable or Semi-Portable Starch Damage Testing Systems | Smaller systems for decentralized testing environments. | Simplified enzymatic detection | Regional mills, contract labs | Compact enzymatic test systems |

| Software and Data Analysis Platforms for Starch Damage | Data management and trend analysis tools linked to analyzers. | QC software, SPC analytics | Large milling groups, central labs | Chopin Lab Software, QC data platforms |

For Detailed Pricing and Tailored Market Report Options, Click Here: https://www.towardsfnb.com/checkout/5958

Damaged Starch Analyzer Market Dynamics

What Are the Growth Drivers of the Damaged Starch Analyzer Market?

Higher demand to maintain quality control in flour milling, the growing food and beverage industry, and the ever increasing demand for bakery and processed food items are major contributors to the market's growth. The market is also observed to grow due to technological advancements that enable immediate, easy detection of flour quality, further fueling the market's growth. Such instruments help the food and beverage industries and the baking industry, which further supports market growth. Optimizing milling processes to minimize starch damage is a major driver of market growth.

Challenge

Technical Complexity and Maintaining Standardization Obstruct the Market’s Growth

Measuring starch damage requires enzymatic methods that are complex and not easy for a layperson to perform. Hence, such factors hinder market growth. To manage such issues, the segment requires consistent lab practices to ensure accurate results, which may slow the process and further hamper the market’s growth. Hence, such problems may collectively undermine the market's growth.

Opportunity

Growing Demand for Quality Management Is Helpful for the Growth of the Market

The growing demand for bakery items and processed foods is a major opportunity for market growth. It further drives higher demand for starch-consistent products, thereby propelling the demand for starch analyzers. Hence, these factors collectively help enhance market growth. Accurate measurement of starch damage during the flour milling process is another major factor driving market growth.

Damaged Starch Analyzer Market Regional Analysis

Europe Dominated the Damaged Starch Analyzer Market in 2025

Europe led the damaged starch analyzer market in 2025, driven by higher demand for convenient, processed, and bakery food items. Such items require consistent starch control, further driving demand for starch analyzers in the region. Strict EU regulations, heightened food safety standards, rapid technological advancements, and the demand for high-quality products also help fuel the market in this area. Germany has a major contribution to the region's market growth, driven by higher demand for processed food options, rising technological advancements, and the growing demand for starch-consistent options, further fueling the market's growth.

Asia Pacific Is Observed to Be the Fastest-Growing Region in the Foreseeable Period

Asia Pacific is expected to be the fastest-growing region over the forecast period, driven by rapid urbanization, a growing bakery industry, rising disposable income, and higher demand for processed food. Technological advancements that help maintain starch consistency across various food options are another major factor driving the market's growth in the foreseeable period.

Growing e-commerce platforms in the region, allowing people to shop for a wide range of products, also help fuel the market’s growth in the foreseeable future. India has made a major contribution to the region's market growth, as the country is the largest exporter of starch-based products worldwide, and has also seen major technological advancements.

North America Is Observed to Have a Notable Growth in the Foreseen Period

North America is expected to show notable growth in the forecast period due to higher demand for naturally processed food options, clean-label products, and starch-consistent options. Rising technological advancements, the use of analytical tools for accurate starch measurement, and the region's growing food and beverage industry are major factors driving market growth. The US and Canada have made major contributions to the market's growth through technological advancements and higher demand for processed options.

Trade Analysis for the Damaged Starch Analyzer Market

What Is Actually Traded (Product Forms and HS Proxies)

- Damaged starch analyzers based on enzymatic or amperometric methods, traded as laboratory instruments and commonly declared under HS 9027 for physical or chemical analysis apparatus.

- Integrated quality-control systems combining damaged starch measurement with other flour parameters, also recorded under HS 9027.

- Reagents, enzymes, and calibration kits are supplied for use with proprietary analyzer platforms, typically cleared under chemical or prepared laboratory reagent headings depending on composition.

Top Exporters (Supply Hubs)

- United States: Exporter of grain and flour analytical instruments supported by strong food-quality instrumentation manufacturers and cereal research infrastructure.

- Germany: Major exporter of laboratory and process-control instruments, including milling and grain-quality analyzers, supported by precision engineering clusters.

- Japan: Exporter of high-precision analytical equipment and sensors used in food quality control, including milling applications.

- France and Switzerland: Suppliers of cereal-testing instruments and laboratory systems used by mills and research laboratories. (Source: https://oec.world/en/profile/hs/9027)

Top Importers (Demand Centres)

- China: Large flour-milling industry and expanding quality-control requirements drive imports of analytical equipment for wheat and flour testing.

- India: Growing industrial milling and packaged food sectors increase demand for flour-quality analyzers in mills and central laboratories.

- European Union: Intra-EU trade supports the replacement and upgrading of analytical instruments in established milling industries.

- Middle East and North Africa: High dependence on imported wheat and flour quality assurance drives investment in testing equipment by mills and government laboratories.

Typical Trade Flows and Logistics Patterns

- Instruments are shipped as high-value capital goods from North America, Europe, and Japan to milling hubs worldwide via air or containerised sea freight.

- Installation and commissioning often involve bundled exports of equipment, proprietary reagents, and software licences.

- After-sales services, calibration support, and reagent replenishment create recurring cross-border trade flows linked to installed analyzer bases.

- Online or at-line analyzers are frequently integrated into new milling lines supplied by international equipment vendors.

Trade Drivers and Structural Factors

- Milling process optimisation: Higher roller pressures and throughput require precise monitoring of damaged starch to balance yield and flour functionality.

- Industrial baking specifications: Large bakeries specify damaged starch ranges to control water absorption and fermentation performance.

- Automation and digitalisation: Integration of analyzers into quality-management systems increases demand for standardised, repeatable instruments.

- Grain variability: Climate-driven variability in wheat hardness increases reliance on analytical measurement rather than visual or manual assessment.

Regulatory, Quality, and Market-Access Considerations

- Analytical instruments must comply with electrical safety, electromagnetic compatibility, and laboratory equipment standards in importing markets.

- Many buyers require methods aligned with recognised standards, such as ICC, AACC, or ISO, for determining damaged starch.

- Documentation typically includes conformity certificates, method validation data, and calibration protocols.

- Government and third-party laboratories may require method accreditation for results to be accepted in official inspections or disputes.

Government Initiatives and Public-Policy Influences

- Public investment in grain-quality laboratories and food-safety infrastructure supports procurement of analytical equipment in developing regions.

- National wheat quality monitoring programs encourage the adoption of standardised testing methods and instruments.

- Trade facilitation for laboratory equipment and scientific instruments in some regions reduces tariff and non-tariff barriers.

Damaged Starch Analyzer Market Report Scope

| Report Attribute | Key Statistics |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Growth Rate from 2026 to 2035 | CAGR of 5.8% |

| Market Size in 2026 | USD 171.52 Billion |

| Market Size in 2027 | USD 181.47 Billion |

| Market Size by 2035 | USD 284.90 Billion |

| Dominated Region | Europe |

| Fastest Growing Region | Asia Pacific |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Have Questions? Let’s Talk—Schedule a Meeting with Our Insights Team: https://www.towardsfnb.com/schedule-meeting

Damaged Starch Analyzer Market Segmental Analysis

Technology Analysis

The enzymatic-based analyzer segment dominated the damaged starch analyzer market in 2025, as it provides specific, reproducible, and gold-standard results, further fueling market growth. Hence, such analyzers are widely used by institutions and research centers, driving market growth. The segment also helps market growth, as it serves as the standard reference method for calibrating others due to its high reliability. Hence, these factors collectively help fuel the market’s growth.

The NIR analyzers segment is expected to grow over the forecast period, as the method is cost-effective, non-destructive, and a rapid alternative to traditional wet chemical methods, which are time-consuming. The segment also helps manage damaged starch and maintain consistent quality in starch-based food options, further fueling market growth. The segment enables real-time decision-making and delivers results in minutes, further fueling the market's growth in the foreseeable future.

Product Analysis

The benchtop analyzer segment dominated the damaged starch analyzer market in 2025, as it is a cost-effective and productive method, fueling market growth. It is an automated procedure and is helpful for the baking and flour milling industry. Benchtop analyzers such as CHOPIN SDmatic 2 use recognized, standardized methods to deliver accurate results and final outputs, further fueling the market's growth.

The portable handheld analyzer segment is expected to grow over the forecast period, as it provides cost-effective, rapid quality control in the food and beverage and bakery industries. Providing instant feedback in a production environment is another major factor driving market growth in the foreseeable future. The segment also helps lower costs by eliminating the need for expensive handheld analyzers and trained technical staff.

Application Analysis

The flour milling quality control segment dominated the damaged starch analyzer market in 2025, driven by higher demand for tools to detect starch inconsistencies and for instruments to measure them. The milling process is considered a major source of damaged starch, along with crucial factors such as roll speed, roll gap, and wheat hardness, further fueling the market's growth.

The baking and ingredient manufacturing segment is expected to grow in the foreseeable period, as damaged starch directly affects the quality of the final product. Hence, the segment ensures the management of factors such as fermentation, dough handling, enzyme activity, and flour’s water absorption to produce breads and cookies, thereby helping fuel the market's growth in the forecast period.

Feel Free to Get in Touch with Us for Orders or Any Questions at: sales@towardsfnb.com

Additional Topics Worth Exploring:

- Dietary Supplements Market: The dietary supplements market size is projected to reach USD 464.58 billion by 2034, growing from USD 192.68 billion in 2025, at a CAGR of 9.2% from 2025 to 2034.

- Frozen Food Market: The global frozen food market size is expected to grow from USD 214.32 billion in 2025 to reach around USD 347.01 billion by 2034, at a CAGR of 5.5% over the forecast period from 2025 to 2034.

- Vegan Food Market: The global vegan food market size is evaluated at USD 22.38 billion in 2025 and is expected to reach USD 55.88 billion by 2034, with a CAGR of 10.7% during the forecast period from 2025 to 2034.

- Sugar-Free Food Market: The global sugar-free food market size is expected to grow from USD 48.14 billion in 2025 to USD 83.2 billion by 2034, growing at a CAGR of 6.27% during the forecast period from 2025 to 2034.

- Food Additives Market: The global food additives market size is rising from USD 128.14 billion in 2025 to USD 214.66 billion by 2034. This projected expansion reflects a CAGR of 5.9% throughout the forecast period from 2025 to 2034.

- Ethnic Food Market: The global ethnic food market size is forecasted to expand from USD 93.47 billion in 2025 to reach around USD 179.21 billion by 2034, growing at a CAGR of 7.5% during the forecast period from 2025 to 2034.

- Meal Kits Market: The global meal kits market size is projected to rise from USD 17.11 billion in 2025 to approximately USD 58.8 billion by 2034, registering a CAGR of 14.7% during the forecast period from 2025 to 2034.

- Baking Ingredients Market: The global baking ingredients market size is projected to grow from USD 18 billion in 2025 to around USD 31.72 billion by 2034, at a CAGR of 6.5% during the forecast period from 2025 to 2034.

- Fresh Produce Market: The global fresh produce market size is projected to grow from USD 3,707 billion in 2025 to approximately USD 5,653 billion by 2034. This anticipated growth represents a CAGR of 4.80% during the forecast period from 2025 to 2034.

- Beverage Packaging Market: The global beverage packaging market size is projected to reach USD 271.80 billion by 2034, growing from USD 173.71 billion in 2025, at a CAGR of 5.1% during the forecast period from 2025 to 2034.

- Coconut Products Market: The global coconut products market size is expected to climb from USD 14.18 billion in 2025 to approximately USD 33.71 billion by 2034, growing at a CAGR of 10.1% during the forecast from 2025 to 2034.

- Pet Food Market: The global pet food market size is expected to increase from USD 113.02 billion in 2025 to USD 167.97 billion by 2034, growing at a CAGR of 4.5% throughout the estimated timeframe from 2025 to 2034.

- Organic Food Market: The global organic food market size is expected to grow from USD 253.96 billion in 2025 to USD 660.25 billion by 2034, with a compound annual growth rate (CAGR) of 11.20% during the forecast period from 2025 to 2034.

Top Companies in the Damaged Starch Analyzer Market

- Nanosens: Nanosens is a Turkey-based R&D-driven technology provider specializing in spectroscopy-based analytical solutions, including NIR and other optical systems that support rapid quality measurement in food and agricultural applications, such as damaged starch analysis. The company’s innovation focus on fast, non-destructive testing enhances real-time process control for mills and food processors.

- Erkaya: Erkaya offers robust and user-friendly damaged starch analyzers and related grain analysis equipment designed to support flour mills and food laboratories with reliable quality control data using amperometric methods. Its product portfolio emphasizes practical operation and production optimization, helping customers fine-tune milling settings and final product characteristics.

- SAYTEK: SAYTEK provides a broad range of food quality control instruments, including damaged starch analyzers as part of its laboratory equipment lineup, supporting comprehensive testing in flour, grain, and food quality management. With a focus on sustainability and innovative technology adoption, the company addresses evolving industry needs for accuracy and environmental responsibility in quality testing.

- Yucebas Machinery Analytical Equipment Industry: Yucebas Machinery specializes in analytical and process testing solutions for cereal and flour quality, including damaged starch analysis devices, and integrates scientific collaboration to bridge theoretical research and practical instrumentation. The company focuses on tailored analytical equipment that supports quality laboratories and processing operations with precise measurement capabilities.

Segments Covered in the Report

By Technology Type

- Enzymatic-Based Analyzers

- Near-Infrared (NIR) Analyzers

- Image Analysis / Optical Analyzers

- Chemical Titration-Based Analyzers

By Product Type

- Benchtop Damaged Starch Analyzers

- Portable / Handheld Analyzers

- Integrated Flour Quality Testing Systems

By Application

- Flour Milling Quality Control

- Baking & Bakery Ingredient Manufacturing

- Food Quality & Assurance Labs

- Research & Academic Institutions

By Region

North America

- U.S.

- Canada

Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

Latin America

- Brazil

- Mexico

- Argentina

Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Thank you for exploring our insights. For more targeted information, customized chapter-wise sections and region-specific editions such as North America, Europe, or Asia Pacific—are also available upon request.

For Detailed Pricing and Tailored Market Report Options, Click Here: https://www.towardsfnb.com/checkout/5958

Feel Free to Get in Touch with Us for Orders or Any Questions at: sales@towardsfnb.com

Unlock expert insights, custom research, and premium support with the Towards FnB Annual Membership. For USD 495/month (billed annually), get full access to exclusive F&B market data and personalized guidance. It’s your strategic edge in the food and beverage industry: https://www.towardsfnb.com/get-an-annual-membership

About Us

Towards FnB is a global consulting firm specializing in the food and beverage industry, providing innovative solutions and expert guidance to elevate businesses. With an in-depth understanding of the dynamic F&B sector, we deliver customized market analysis and strategic insights. Our team of seasoned professionals is committed to empowering clients with the knowledge needed to make informed decisions, ensuring they stay ahead of market trends. Partner with us as we redefine success in the rapidly evolving food and beverage landscape, and together, we’ll navigate this transformative journey.

Web: https://www.towardsfnb.com/

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Packaging | Towards Chemical and Materials| Nova One Advisor | Food Beverage Strategies | FnB Market Pulse | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us:

Discover More Market Trends and Insights from Towards FnB:

➡️Salt Market: https://www.towardsfnb.com/insights/salt-market

➡️Gluten-Free Bakery Market: https://www.towardsfnb.com/insights/gluten-free-bakery-market

➡️Canned Food Market: https://www.towardsfnb.com/insights/canned-food-market

➡️Dry Fruit Market: https://www.towardsfnb.com/insights/dry-fruit-market

➡️Frozen Meat Market: https://www.towardsfnb.com/insights/frozen-meat-market

➡️Fish Oil Market: https://www.towardsfnb.com/insights/fish-oil-market

➡️Soft Drink Concentrates Market: https://www.towardsfnb.com/insights/soft-drink-concentrates-market

➡️Coffee Beans Market: https://www.towardsfnb.com/insights/coffee-beans-market

➡️Soybean Market: https://www.towardsfnb.com/insights/soybean-market

➡️Beef Market: https://www.towardsfnb.com/insights/beef-market

➡️Cheese Market: https://www.towardsfnb.com/insights/cheese-market

➡️Food Packaging Market: https://www.towardsfnb.com/insights/food-packaging-market