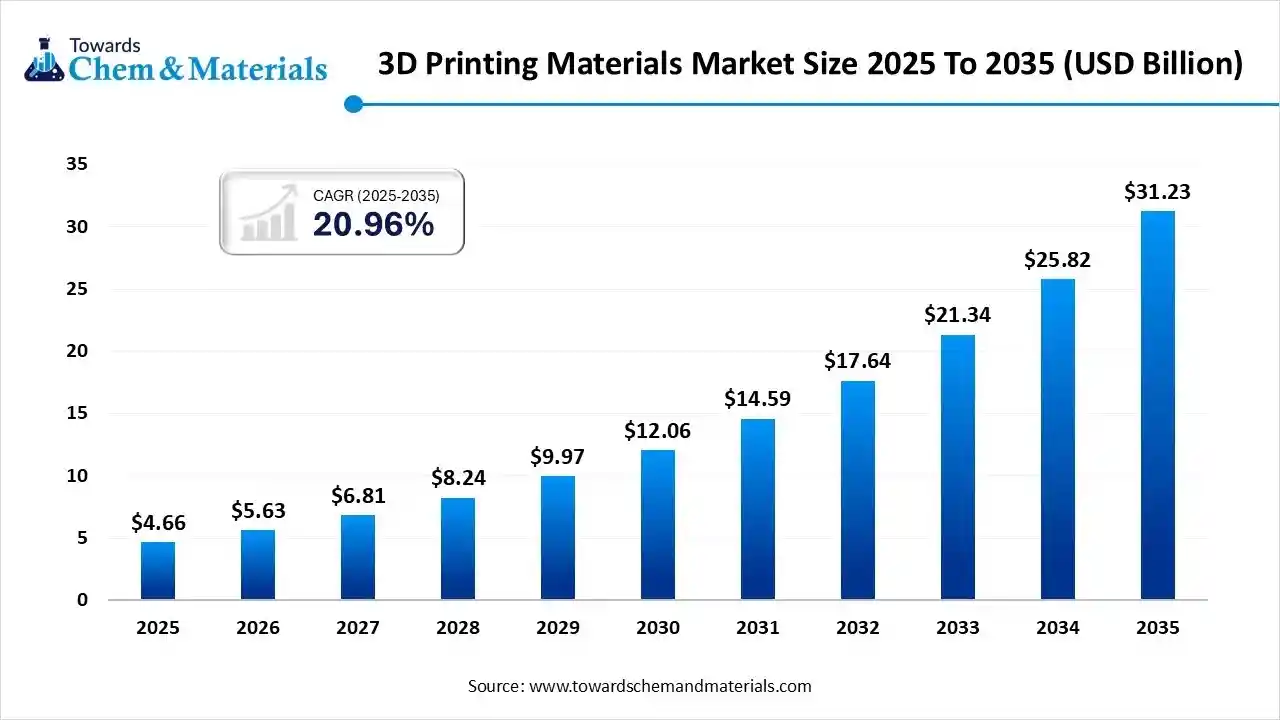

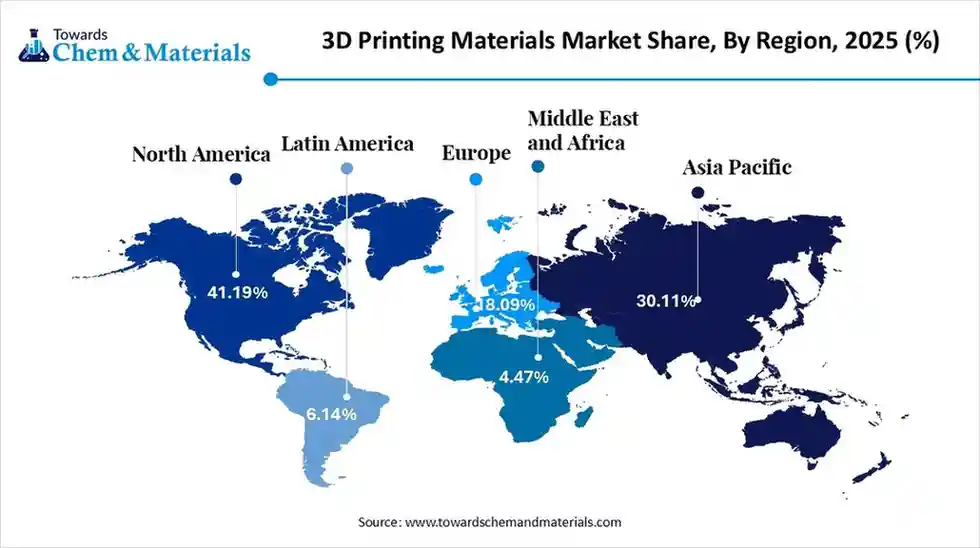

Ottawa, Dec. 10, 2025 (GLOBE NEWSWIRE) -- The global 3D printing materials market size reached at USD 4.66 billion in 2025 and is predicted to increase by USD 5.63 billion in 2026 and is expected to be worth around USD 31.23 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 20.96% over the forecast period 2026 to 2035. North America dominated the 3D printing materials market with the largest revenue share of 41.19% in 2025. The 3D printing materials market grew in 2025 due to rising demand for lightweight and customizable parts. Companies used additive manufacturing for faster prototyping and low-volume production. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/6055

What are 3D Printing Materials?

The 3D printing materials market in 2025 experienced strong growth as additive manufacturing moved deeper into commercial production across aerospace, automotive, healthcare, and consumer sectors. Demand shifted from basic prototyping materials to advanced thermoplastics, metal powders, composites, and biocompatible resins that offer higher strength, temperature resistance, and functional performance. Companies increasingly adopted 3D printing for faster design cycles, lightweighting, on-demand manufacturing, and customized products, which expanded material consumption.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

3D Printing Materials Market Report Highlights

- By region, North America led the 3D Printing Materials market with the largest revenue share of over 41.19% in 2025.

- By product, the photopolymers segment led the market with the largest revenue share of 38.5% in 2025.

- By application, the aerospace and defense sectors segment led the market with the largest revenue share of 25.9% in 2025.

- By application, the automotive segment accounted for the largest revenue share of 31.6% in 2025.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6055

How 3D printing is changing the world

Because of the capabilities and advances in materials, 3D printing has already changed several industries forever.

In manufacturing, it’s not an either-or proposition of using subtractive or additive methods. A London design company is already deploying a huge additive-manufacturing tool in traditional factory settings to create a hybrid model.

It’s also expanding the possibilities for what can be made. Health care is a great example, where additively manufactured skin, titanium bones and joints, and even blood vessels count among the innovations.

The construction innovations are even more advanced—and have great potential to change the industry. Additive practices are already established enough for calls to properly regulate the field with relevant and updated building codes.

To benefit the social good, you can start with the fact that dwellings are expensive. Lots of people simply can’t afford them, so if it’s possible to build a home in a single day for the cost of a decent second-hand car, this could help lift tens of millions out of poverty.

Additive manufacturing also offers efficiencies regular construction doesn’t. Housing is normally built in a linear process: erecting the frame, laying bricks, applying roof trusses—all readying the project for glaziers and plumbers to work on later.

Compare Plastic 3D Printing Materials and Processes

Different 3D printing materials and plastic 3D printing processes have their own strengths and weaknesses that define their suitability for different applications. The following table provides a high level summary of some key characteristics and considerations.

| FDM | SLA | SLS | |

| Pros | Low-cost consumer machines and materials available | Great value High accuracy Smooth surface finish Range of functional materials | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design compatibility High cost industrial machines if accuracy and high performance materials are needed | Sensitive to long exposure to UV light | More expensive hardware Limited material options |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models Select end-use parts with high-end industrial machines and materials | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Models and props | Functional prototyping Short-run, bridge, or custom manufacturing |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends on consumer level machines. High performance composites on high cost industrial machines | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). Pure silicone and ceramic. |

Popular FDM 3D Printing Materials

The most common FDM 3D printing materials are ABS, PLA, and their various blends. More advanced FDM printers can also print with other specialized materials that offer properties like higher heat resistance, impact resistance, chemical resistance, and rigidity.

| Material | Features | Applications |

| ABS (acrylonitrile butadiene styrene) | Tough and durable Heat and impact resistant Requires a heated bed to print Requires ventilation | Functional prototypes |

| PLA (polylactic acid) | The easiest FDM materials to print Rigid, strong, but brittle Less resistant to heat and chemicals Biodegradable Odorless | Concept models Looks-like prototypes |

| PETG (polyethylene terephthalate glycol) | Compatible with lower printing temperatures for faster production Humidity and chemical resistant High transparency Can be food safe | Waterproof applications Snap-fit components |

| Nylon | Strong, durable, and lightweight Tough and partially flexible Heat and impact resistant Very complex to print on FDM | Functional prototypes Wear resistant parts |

| TPU (thermoplastic polyurethane) | Flexible and stretchable Impact resistant Excellent vibration dampening | Flexible prototypes |

| PVA (polyvinyl alcohol) | Soluble support material Dissolves in water | Support material |

| HIPS (high impact polystyrene) | Soluble support material most commonly used with ABS Dissolves in chemical limonene | Support material |

| Composites (carbon fiber, kevlar, fiberglass) | Rigid, strong, or extremely tough Compatibility limited to some expensive industrial FDM 3D printers | Functional prototypes Jigs, fixtures, and tooling |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

How AI Became the New Engine Powering the 3D Printing Materials Revolution?

AI became the new engine powering the 3D printing materials revolution in 2025 by accelerating material discovery, optimizing formulations, and improving print performance through data-driven insights. Machine-learning models enabled rapid testing of thousands of material combinations, leading to stronger, lighter, and more heat-resistant polymers, metals, and composites. AI-powered simulation tools predict material behavior during printing, reducing failures and enhancing surface quality and dimensional accuracy. In manufacturing, AI optimized printer settings in real time, cutting waste and improving consistency across large production runs.

Private Industry Investments for 3D Printing Materials

- Carbon: Specializing in Digital Light Synthesis (DLS) technology, Carbon produces proprietary resin materials designed for applications in industries like automotive, medical, and consumer goods.

- Nano Dimension: This company specializes in the development and manufacturing of electronics, producing inks and materials for high-precision 3D printed circuit boards.

- Materialise: Beyond offering 3D printing services, Materialise invests heavily in software and medical-grade materials, particularly for customized implants and surgical guides.

- Velo3D: This company offers advanced, integrated metal additive manufacturing solutions, including proprietary powders, primarily serving the aerospace, defense, and energy industries.

- Polymaker: A global company based in China, Polymaker focuses on developing a wide variety of high-quality 3D printing filaments for a range of uses, from consumer to industrial applications.

What are the Major Trends of the 3D Printing Materials Market?

- Shift to high-performance and composite materials:

Material science advancements are leading to the development of advanced polymers, metals (like titanium and nickel alloys), ceramics, and composites (e.g., carbon fiber-reinforced polymers) with enhanced properties. These materials offer properties such as high strength, heat resistance, and durability, enabling their use in demanding applications across aerospace and automotive industries. - Growing emphasis on sustainability:

Environmental concerns are driving the demand for eco-friendly solutions, including filaments made from recycled plastics, bio-based polymers, and solvent-free resins. This trend not only helps meet sustainability goals and regulations but also reduces material waste compared to traditional manufacturing methods. - Transition from prototyping to end-use production:

While 3D printing was initially used primarily for rapid prototyping, technological advancements have enabled the reliable production of functional, end-use parts. This shift is particularly evident in industries like healthcare (for patient-specific implants and prosthetics) and aerospace (for complex engine components), where high performance and customization are critical.

Market Opportunity

The Rise of High-Performance Composites: 3D Printing's Next Billion-Dollar Opportunity

The rise of high-performance composites is emerging as one of the most transformative and lucrative opportunities in 3D printing materials because these materials combine lightweight properties with exceptional mechanical performance, enabling applications that traditional polymers or metals cannot easily achieve. Carbon-fiber- and glass-fiber-reinforced composites deliver superior strength, stiffness, and fatigue resistance, making them ideal for aerospace components, EV battery housings, motorsport parts, industrial tools, and structural brackets.

Advancements in continuous-fiber 3D printing are unlocking the ability to create load-bearing, metal-replacement parts with highly optimized geometries, reducing weight by up to 60–80% while maintaining structural integrity.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6055

3D Printing Materials Market Segmentation Insights

Product Insights

What Made the Photopolymers Segment Dominate the 3D Printing Materials Market in 2025?

In 2025, the photopolymers segment dominated the market due to its unmatched ability to deliver high-resolution, smooth-surface, and intricately detailed parts, making it ideal for applications in the dental, medical, jewelry, and eyewear industries. Advances in vat-photopolymerization technologies and faster, more reactive resin chemistries improved printing speed and reliability, enabling short-run production beyond prototyping. The launch of engineering-grade, biocompatible, and specialty resins expanded their industrial applications, while a mature ecosystem of compatible printers, post-processing systems, and scalable supply chains made photopolymers more cost-effective and widely accessible.

The thermoplastics segment is expected to grow fastest over the forecast period because it offered the most cost-effective, versatile, and scalable solution for both consumer and industrial applications, driven by the widespread use of FDM/FFF printers that primarily rely on thermoplastic filaments. Their broad material range, from affordable PLA and ABS for prototyping to advanced engineering polymers like nylon, PEI, and PEEK for aerospace, automotive, and medical end-use parts, enabled thermoplastics to meet diverse performance requirements while keeping production simple and economical.

Application Insights

Which Application Segment Dominated the 3D Printing Materials Market in 2025?

The aerospace and defense sectors segment dominated the market in 2025 because they relied heavily on additive manufacturing for lightweighting, part consolidation, and rapid production of complex, high-performance components that traditional manufacturing could not achieve efficiently. Their stringent requirements for strength-to-weight ratio, thermal stability, and reliability accelerated adoption of advanced materials such as high-performance thermoplastics (PEEK, PEI), metal powders, and aerospace-grade photopolymers. These sectors also benefited from significant government and defense investments aimed at improving supply-chain resilience, reducing lead times for critical parts, and enabling on-demand manufacturing for maintenance, repair, and overhaul (MRO).

The automotive segment is expected to grow fastest over the forecast period because automakers are increasingly integrating additive manufacturing into prototyping, tooling, customization, and low-volume production to cut costs, shorten design cycles, and improve manufacturing flexibility. Growing adoption of lightweight thermoplastics, metal powders, and composite-filled materials enabled the production of durable, heat-resistant, and structurally reliable components for interiors, under-the-hood parts, and functional prototypes. Automakers also expanded the use of 3D printing for rapid tooling, jigs, and fixtures, significantly reducing lead times and improving assembly efficiency.

3D Printing Materials Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 5.63 billion |

| Revenue forecast in 2035 | USD 31.23 billion |

| Growth rate | CAGR of 20.96% from 2026 to 2035 |

| Base year for estimation | 2025 |

| Historical data | 2018 - 2025 |

| Forecast period | 2025 - 2035 |

| Quantitative units | Revenue in USD million/billion and CAGR from 2025 to 2035 |

| Report coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments covered | By Product, By Application, By Region |

| Regional scope | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

| Country scope | U.S., Canada, Mexico, Germany, UK, France, Italy, Spain, China, India, Japan, Brazil, Argentina |

| Key companies profiled | ATI; CNPC Powder; Colibrium Additive; GKN Powder Metallurgy; Höganäs AB; Kennametal Inc.; Arkema Inc; CRP Technology; Stratasys Ltd.; Saudi Basic Industries Corporation (SABIC); Polyone Corporation |

➤ Contact Us: sales@towardschemandmaterials.com | ☎ +1 804 441 9344

Regional Insights

North America Takes the Lead: The Powerhouse Driving the 3D Printing Materials Market

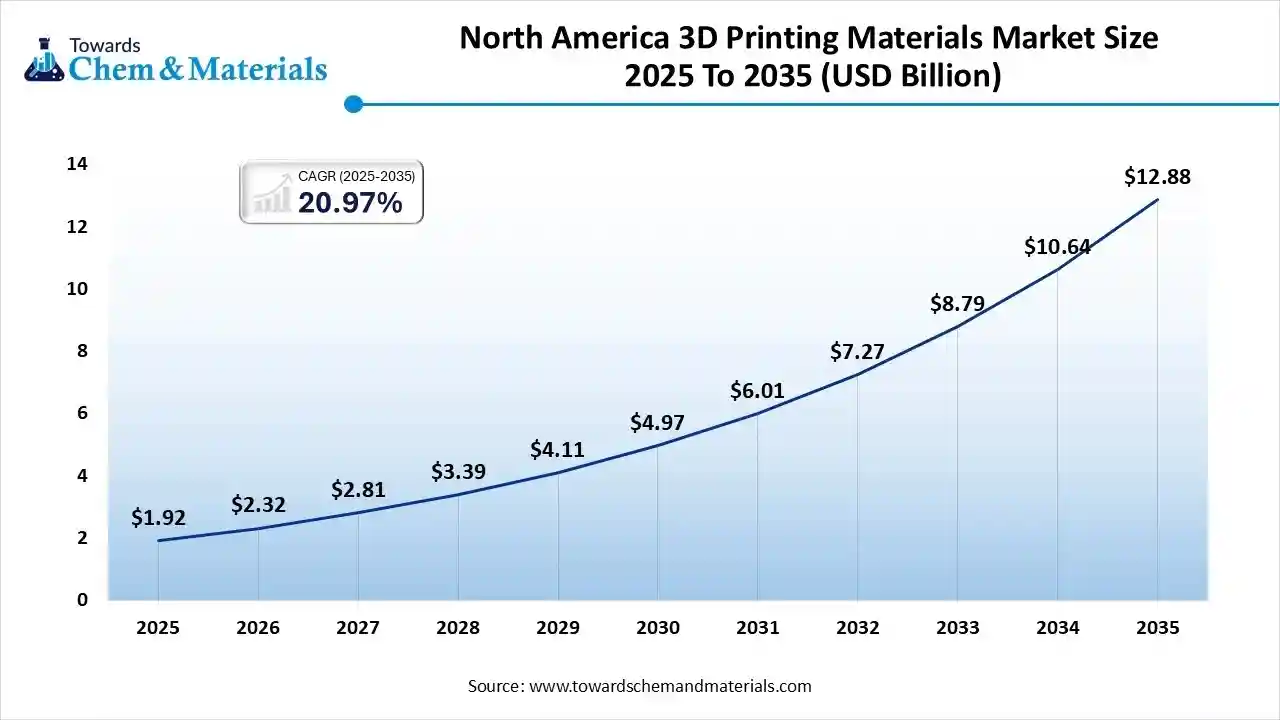

The North America 3D printing materials market size was valued at USD 1.92 billion in 2025 and is expected to reach USD 12.88 billion by 2035, growing at a CAGR of 20.97% from 2026 to 2035. North America led the 3D Printing Materials market with the largest revenue share of over 41.19% in 2025.

North America dominated the market in 2025 because the region had a strong ecosystem of advanced manufacturers, leading technology providers, and major aerospace, automotive, and healthcare players that accelerated material adoption. Heavy investment in R&D, especially in high-performance thermoplastics, metal powders, and composite materials, positioned the US as a global innovation hub. Government-backed initiatives supporting defense, space exploration, and digital manufacturing further boosted demand for certified, high-quality 3D printing materials.

Canada 3D Printing Materials Market Trends

In 2025, Canada's market experienced significant growth, fueled by rising adoption across aerospace, healthcare, automotive, and educational sectors. The demand was driven by the need for rapid prototyping, customized manufacturing, low-volume production, and lightweight, high-performance components. Thermoplastics remained the dominant material, while metal powders, high-performance composites, and biocompatible resins gained traction for industrial and medical applications. Government initiatives promoting advanced manufacturing, innovation hubs, and research collaborations supported the development and adoption of cutting-edge and sustainable materials.

Asia Pacific Surges Ahead: The Fastest-Growing Frontier in 3D Printing Materials

Asia Pacific became the fastest-growing region in the market in 2025 due to rapid industrial expansion, strong government investments, and rising adoption of additive manufacturing across automotive, electronics, aerospace, and healthcare sectors. Countries like China, Japan, South Korea, and India accelerated manufacturing digitalization, driving demand for high-performance thermoplastics, metal powders, and composite materials. Expanding EV production, advanced electronics manufacturing, and medical device innovation significantly boosted the need for lightweight, customizable, and cost-efficient 3D printing materials.

India 3D Printing Materials Market Trends

In 2025, India's market showed rapid growth driven by increasing adoption in automotive, aerospace, healthcare, and electronics sectors. Rising demand for rapid prototyping, low-volume production, and customized parts fueled the use of thermoplastics, metal powders, and composite materials. Government initiatives supporting Make in India, digital manufacturing, and Industry 4.0 adoption encouraged investments in advanced 3D printing technologies and materials.

Top Companies in the 3D Printing Materials Market & Their Offerings:

- ATI: Provides high-performance titanium and specialty metal powders for aerospace and medical 3D printing.

- CNPC Powder: Manufactures and supplies a wide range of metal powders, including aluminum, titanium, copper, nickel, and iron-based alloys.

- Colibrium Additive: Offers high-performance metal powders like titanium and cobalt-chromium alloys alongside 3D printing machines.

- GKN Powder Metallurgy: Provides a comprehensive portfolio of metal powders and components, including stainless and low-alloy steels.

- Höganäs AB: A major supplier of cost-effective metal powders focused on sustainable production.

- Kennametal Inc.: Develops and supplies various metal powders and advanced material solutions for industrial 3D printing.

- Arkema Inc.: Provides high-performance polymers for 3D printing, including Rilsan® bio-based polyamides and Kepstan® PEKK.

- CRP Technology: Specializes in producing high-performance, carbon fiber-reinforced composite materials (Windform®) for professional 3D printing.

- Saudi Basic Industries Corporation (SABIC): Offers high-performance thermoplastic materials like ULTEM™ and LEXAN™ resins for industrial applications.

- PolyOne Corporation (Avient): Provides specialized polymer material solutions, including innovative filaments and powders for 3D printing.

More Insights in Towards Chemical and Materials:

- High-Temperature Insulation Materials Market size to Reach USD 16.09 Bn by 2034

- Asia Pacific Green Materials Market Volume to Reach 205.45 Million Tons by 2034

- Europe Green Building Materials Market Volume to Reach 406.7 Million Tons by 2034

- Biomaterials Market Size to Surge USD 526.63 Billion by 2034

- Smart Building Materials Market Size to Hit USD 115.85 Bn by 2035

- Circular Construction Materials Market Size to Reach USD 267.14 Billion by 2035

- Aerospace Materials Market Size to Reach USD 112.78 Bn by 2035

- Advanced Carbon Materials Market Size to Hit USD 86.27 Bn by 2035

- Mycelium-Based Building Materials Market Size to Hit USD 3.81 Bn by 2035

- Cork Building Materials Market Size to Hit USD 20.82 Bn by 2035

- Aerospace and Defense Materials Market Size to Surpass USD 49.07 Bn by 2035

- Advanced Composite Materials Market Size to Surpass USD 102.15 Bn by 2035

- U.S. Nanomaterials Market Size to Worth Around USD 14.41 Bn by 2034

- Sustainable Materials Market Size to Hit USD 1078.35 Bn by 2034

- Asia Pacific Battery Raw Materials Market Size to Hit USD 93.11 Bn by 2034

- U.S. Metamaterials Market Size to Surge USD 4,996.74 Million by 2034

- Building & Construction Materials Market Size to Reach USD 3.90 Trillion by 2034

- Building Materials Market Size to Reach USD 2.17 Trillion by 2034

- U.S. Biomaterials Market Size to Surge USD 272.18 Billion by 2034

- Electronic Materials And Chemicals Market Size to Surge USD 136.03 Bn by 2034

- U.S. Recycled Plastics in Green Building Materials Market Size and Top Companies Analysis, 2034

- Energy Dense Materials Market Size to Reach USD 211.44 Bn by 2034

- Aluminum Composite Materials Market Size to Reach USD 8.18 Billion by 2034

- Recycled Plastics In Green Building Materials Market Size to Reach USD 12.24 Bn by 2034

3D Printing Materials Market Top Key Companies:

- ATI

- CNPC Powder

- Colibrium Additive

- GKN Powder Metallurgy

- Höganäs AB

- Kennametal Inc.

- Arkema Inc.

- CRP Technology

- Stratasys Ltd.

- Saudi Basic Industries Corporation (SABIC)

- Polyone Corporation

Recent Developments

- In June 2025, 3DXTECH, a high-performance 3D printing materials manufacturer, launched its 3DXLabs program. This program enables customers early access to its experimental, R&D-grade materials still under development.

- In June 2023, CRP Technology announced the launch of Windform XT 2.0 IMG, its first injection molding material made entirely from recycled Windform XT 2.0 industrial 3D printing materials. This high-performance composite, reinforced with carbon fibers and based on nylon PA12, aims to enhance sustainability in industrial production. This innovation allows companies to seamlessly transition from 3D printing prototypes to large-scale injection molding without compromising performance while also reducing their carbon footprint by utilizing 100% recycled materials.

- In April 2023, Stratasys announced the successful acquisition of Covestro’s additive manufacturing materials business, significantly enhancing its portfolio of 3D printing materials. This acquisition includes around 60 new materials and a robust intellectual property portfolio, positioning the company to better serve customers across various industries, including aerospace and healthcare. This strategic move is expected to foster innovation and expand their offerings in stereolithography and powder bed fusion technologies, ultimately driving growth in the 3D printing materials market.

3D Printing Materials Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global 3D Printing Materials Market

By Product

- Photopolymers

- Thermoplastics

- Metals

- Others

By Application

- Aerospace & Defense

- Medical

- Automotive

- Consumer Products & Industrial

- Others

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6055

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics | TCM Blog

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/