New York, Jan. 28, 2025 (GLOBE NEWSWIRE) -- Overview

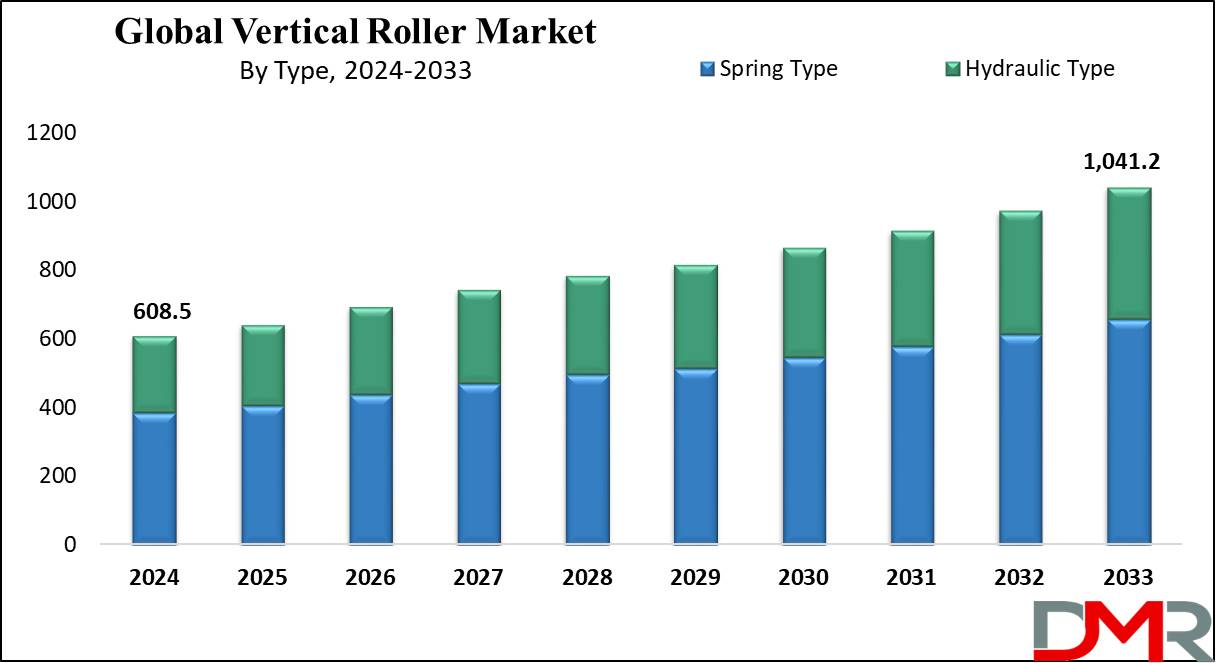

The Global Vertical Roller Mill Market is projected to reach USD 608.5 million in 2024 which is further anticipated to reach USD 1,041.2 million by 2033 at a CAGR of 6.1%.

The global vertical roller mill market is growing, boosted by rises in demand from construction, mining, and industrial sectors, driven by demands for efficiency and energy savings. Poised to drive the market will be developing countries such as India, China, and Brazil, where cement is increasingly demanded, and the mining sector, which is looking toward cost-effective processing.

Another increasing factor in the market is the trend toward digitalization and automation, with smart grinding technologies increasing performance. It, however, faces challenges like high procurement costs, requirement of skilled labor, and fluctuating raw material prices. Despite these issues, the market holds huge potential, especially in North America, the Asia-Pacific, and Europe.

Click to Request Sample Report and Drive Impactful Decisions: https://dimensionmarketresearch.com/report/vertical-roller-mill-market/request-sample/

The US Vertical Roller Mill Market

The US Vertical Roller Mill Market with an estimated value of USD 185.3 million in 2024 is projected to increase at a compound annual growth rate of 5.7% until reaching USD 305.9 million by 2033.

It is being driven by the growing demand for energy-efficient grinding technologies and the extension of large infrastructure projects, especially in the cement industry. Vertical roller mills are preferred as they ensure low power consumption and reduced maintenance costs, aligning with the country's focus on sustainability.

Strict environmental regulations promoting lower carbon emissions also support the adoption of cleaner technologies. Growing demand for better industrial processes will be able to account for regular market growth despite challenges related to high installation costs and competition from alternative technologies for grinding.

Important Insights

- Global Market Value: The global vertical roller mill market is valued at USD 608.5 million in 2024 and is projected to grow to USD 1,041.2 million by 2033.

- US Market Size: The US vertical roller mill market is expected to reach USD 305.9 million by 2033, up from USD 185.3 million in 2024, growing at a CAGR of 5.7%.

- Product Segment: Spring-type vertical roller mills are forecasted to hold 63.1% of the market share by the end of 2024.

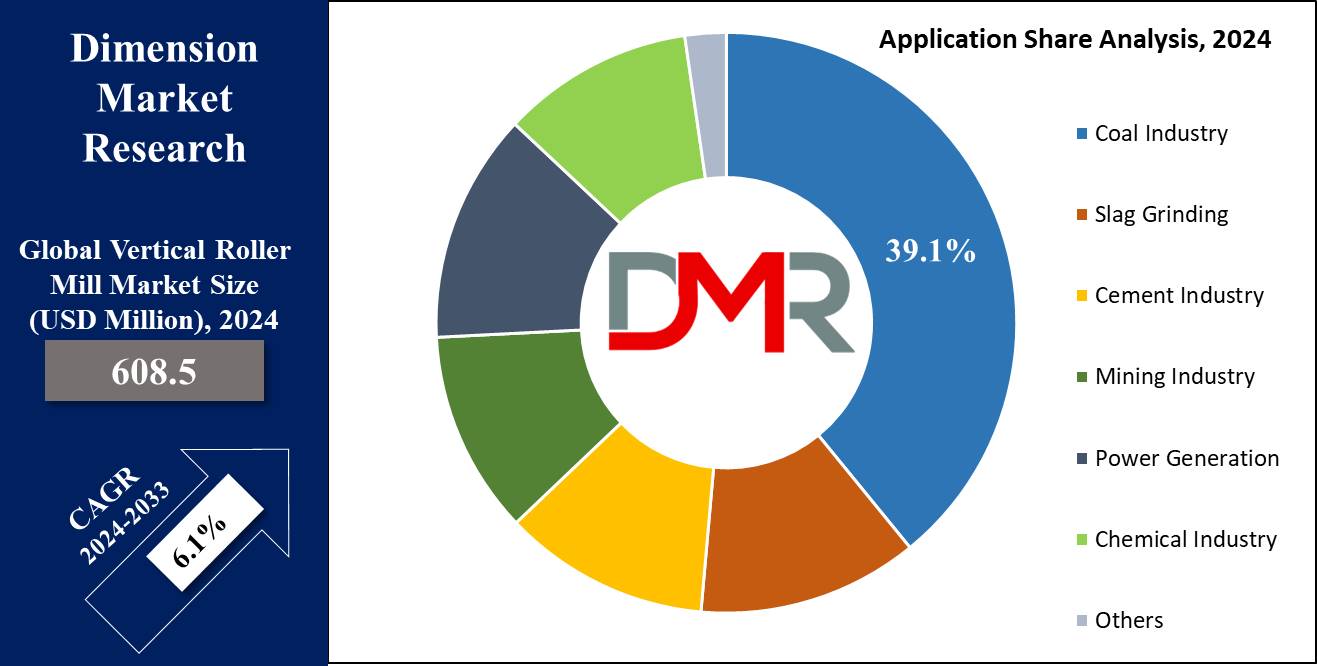

- Application Segment: The coal industry is anticipated to dominate with a 39.1% market share in 2024.

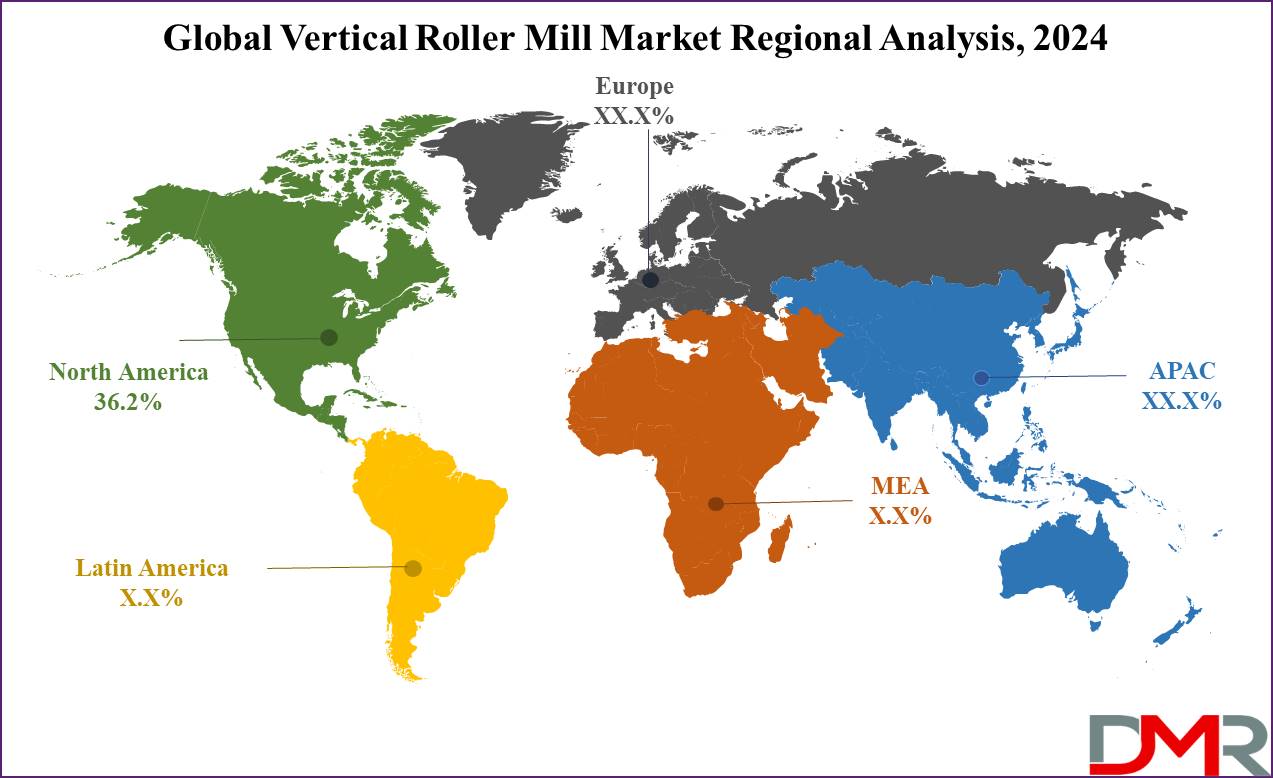

- Regional Analysis: North America is projected to have the largest market share globally, with approximately 36.2% in 2024.

- Global Growth Rate: The market is expanding at a CAGR of 6.1% during the forecast period.

Latest Trends

- As industries prioritize sustainability, technologies that towards a low-carbon economy; hence, technologies that help to decrease the consumption of energy and carbon footprint are increasingly being adopted. Vertical roller mills may reduce energy consumption by as much as 30% compared with conventional ball mills, and this has made these very popular for cement manufacturing operations whenever the energy tariffs go up.

- The improvement in VRM is continuous through the latest developments in hydraulic systems, automation, and wear-resistant materials, which improve vastly in maintenance cost reduction, quality assurance of products, and monitoring real-time performances. VRM has therefore become more reliable and efficient, and hence industries seek such high-performance grinding

- With the advancement of technology today, VRM is sold by manufacturers for different industries like cement, mining, and chemicals. Because mills can be tailored to suit particular needs regarding size and capacity, their applications vary, and integrating them into existing production lines becomes easier.

Vertical Roller Mill Market: Competitive Landscape

The global vertical roller mill market is highly competitive, with key players like Loesche, FLSmidth, Gebr. Pfeiffer, and Sinoma International Engineering leading through innovation and strategic alliances. These companies focus on improving efficiency, reducing energy consumption, and extending mill operational life. While established players are dominant, regional manufacturers have also started securing a place with cost-effective solutions and locally applicable ones. Competition can be very common, usually fueled by an increase in demand for vertical roller mills tailored towards use within a specific industry-e.g., for demanding tasks within the cement, mining, and chemicals industries. Common strategies include mergers and acquisitions, partnerships, and heavy R&D investments into the development of more energy-efficient and environmentally friendly solutions, hence promising a dynamic competitive landscape for further years.

Some of the prominent market players:

- Loesche GmbH

- Pfeiffer SE

- FLSmidth & Co. A/S

- ThyssenKrupp AG

- Metso Outotec

- Ecutec Barcelona S.L.

- Ube Machinery Corporation

- Fujian Longyi Powder Equipment Manufacturing Co. Ltd.

- Sinoma International Engineering Co. Ltd.

- Shibang Industry & Technology Group (SBM)

- CHAENG (Xinxiang Great Wall Machinery Corporation)

- NHI Group

- AMCL Machinery Limited

- Other Key Players

Transform your business approach with strategic insights from our report. Get in touch to request our brochure today at https://dimensionmarketresearch.com/report/vertical-roller-mill-market/download-reports-excerpt/

Vertical Roller Mill Market Scope

| Report Highlights | Details |

| Market Size (2024) | USD 608.5 Mn |

| Forecast Value (2033) | USD 1,041.2 Mn |

| CAGR (2024-2033) | 6.1% |

| The US Market Size (2024) | USD 185.3 Mn |

| North America Revenue Share (2024) | 36.2% |

| Historical Data | 2018 - 2023 |

| Forecast Data | 2024 - 2033 |

| Base Year | 2023 |

| Estimate Year | 2024 |

| Segments Covered | By Product Type, By Type, By Operation Mode, By Application |

| Regional Coverage | North America, Europe, Asia Pacific, Latin America, Middle East & Africa (MEA) |

Market Analysis

Spring-type vertical roller mills are very likely to lead the market share of about 63.1% in 2024 on account of their constant grinding pressure, high efficiency, and ability to grind variable raw materials. Its wide applications in the cement and mining industries result from aspects of precision and durability. Their robust construction can bear hard materials for grinding with minimal wear, hence reducing maintenance. On the other hand, spring-type mills are best suited to hold more operational stability and cost efficiency on a long-term basis, compared to hydraulic systems, for big-scale industrial operations focusing on energy efficiency and reliability.

Vertical Roller Mill Market Segmentation

By Product Type

- Spring Type

- Hydraulic Type

By Type

- Less Than 200t/h

- 200-400t/h

- More Than 400t/h

By Operation Mode

- Manual Operation

- Semi-Automatic Operation

- Fully Automatic Operation

By Application

- Coal Industry

- Slag Grinding

- Cement Industry

- Mining Industry

- Power Generation

- Chemical Industry

- Others

Purchase the Competition Analysis Dashboard Today at https://dimensionmarketresearch.com/checkout/vertical-roller-mill-market/

Growth Drivers

- The emerging urbanization and construction activities in the Asia-Pacific, Africa, and Latin America are driving the demand for cement. Vertical roller mills, with accompanying energy-efficient grinding, are considered crucial given meeting this demand.

- Governments are putting more stringent restrictions on industries, which is one of the major factors contributing to emissions. Vertical roller mills assist companies in reducing energy consumption and, correspondingly, their emissions, enabling them to meet environmental standards without being less productive.

- Subsidies and grants are provided by many governments for the implementation of such advanced technologies as Vertical roller mills. All this seriously promotes the modernization process in this market and especially helps developing countries to be more competitive in the global market.

Restraints

- Vertical roller mill requires a significant upfront investment, which poses a major restraint for smaller companies. Financing challenges, especially in regions with limited credit access, can further pose an obstacle to the adoption despite long-term benefits.

- Competition from alternative grinding technologies may present competition, as some industries find the costs of adopting Vertical roller mills too high.

Growth Opportunities

- industrialization is on the rise in Southeast Asia, Africa, and Eastern Europe opening several opportunities to VRM manufacturers. Companies can expand their market share through the understanding of regional needs and forming local partnerships.

- AI combined with machine learning offers immense potential for incorporation into the VRM to bring efficiency in predictive maintenance and process optimization. Automated vertical roller mills reduce energy consumption and, therefore, are appealing to forward-thinking companies.

- Diversification of VRM usage from existing industries, industrial minerals, or recycling applications creates new markets. Innovation will, over time, continue to enable diversification from VRM manufacturers and further reduce dependence on historically traditional sectors.

Click to Request Sample Report and Drive Impactful Decisions at https://dimensionmarketresearch.com/checkout/vertical-roller-mill-market/

Regional Analysis

North America, with large industrial foundations, excellent infrastructure, and major cement, mining, and chemical companies, is expected to attain the leading position in the vertical roller mill with a revenue share of 36.2% in 2024. The increasing awareness of sustainability and efficiency in the region, along with severe environmental policies in the U.S. and Canada, has fast-tracked the transition away from conventional ball mills and toward more energy-efficient vertical roller mills. Also, the solid infrastructure of North America and further willingness for innovation are foreseen to continue to foster the demand for Vertical roller mills, particularly in cement and power generation sectors that are assured of their continued leadership through the forecast period.

By Region

North America

- The U.S.

- Canada

Europe

- Germany

- The U.K.

- France

- Italy

- Russia

- Spain

- Benelux

- Nordic

- Rest of Europe

Asia-Pacific

- China

- Japan

- South Korea

- India

- ANZ

- ASEAN

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Rest of Latin America

Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Israel

- Egypt

- Rest of MEA

Discover additional reports tailored to your industry needs

The Global Drilling Fluids Market is expected to reach a value of USD 8,802.2 million in 2023 and grow by 13,398.9 Mn with a CAGR of 4.8% for the forecasted period (2023-2032).

The Global Water Testing Equipment Market is expected to reach a value of USD 4,992.3 million in 2023, and it is projected to show a CAGR of 6.6% for the forecast period (2023 -2032).

The Global Demister Market is expected to reach a value of USD 2.1 billion in 2023, and it is further anticipated to reach a market value of USD 3.0 billion by 2032 at a CAGR of 4.1%.

The Global Micro Turbines Market is expected to reach a value of USD 179.0 million in 2023, and it is further anticipated to reach a market value of USD 435.4 million by 2032 at a CAGR of 10.4%.

The Global Industrial Tubes Market size is expected to be valued at USD 687.1 billion in 2024, and it is further expected to reach a market value of USD 1,373.0 billion by 2033 at a CAGR of 8.0%.

The Global Aircraft Micro Turbine Engine Market is projected to reach USD 2.5 billion in 2024 and grow at a compound annual growth rate of 5.9% from there until 2033 to reach a value of USD 4.3 billion.

The Global Thermoplastic Solenoid Valves Market is projected to reach USD 389.1 million in 2024 and grow at a compound annual growth rate of 5.7% from there until 2033 to reach a value of USD 641.6 million.

The Global Core Cutters Market is projected to reach USD 299.9 million in 2024 and grow at a compound annual growth rate of 5.7% from there until 2033 to reach a value of USD 494.4 million.

Global Stainless Steel Cannula Market is projected to reach USD 187.0 million by the end of 2024 and grow exponentially until an anticipated value of USD 397.0 million in 2033 at a CAGR of 8.7%.

Global Filter Rolling System Market is projected to reach USD 17.5 billion by the end of 2024 and is anticipated to value USD 36.2 billion in 2033 at a CAGR of 8.4%.

Recent Developments in the Global Vertical Roller Mill Market

- September 2023: FLSmidth introduced its next-generation OK™ Mill, featuring advanced technologies to boost energy efficiency and reduce emissions. The mill includes upgraded grinding mechanisms and a real-time digital control system for performance optimization.

- July 2023: Gebr. Pfeiffer commissioned an MVR vertical roller mill at a major Middle Eastern cement plant, designed for high throughput and energy-efficient production of various cement types.

- May 2023: Loesche completed VRM installations at a large coal-fired power plant in Asia, improving coal grinding, combustion efficiency, and reducing emissions.

- March 2023: Sinoma International Engineering secured a major contract to supply vertical roller mills for raw materials, clinker, and coal grinding in a new cement production line in Africa.

About Dimension Market Research (DMR):

Dimension Market Research (DMR) is a market research and consulting firm based in India & US, with its headquarters located in the USA (New York). The company believes in providing the best and most valuable data to its customers using the best resources analysts work, to create unmatchable insights into the industries, and markets while offering in-depth results of over 30 industries, and all major regions across the world. We also believe that our clients don’t always want what they see, so we provide customized reports as well, as per their specific requirements to create the best possible outcomes for them and enhance their business through our data and insights in every possible way.